19

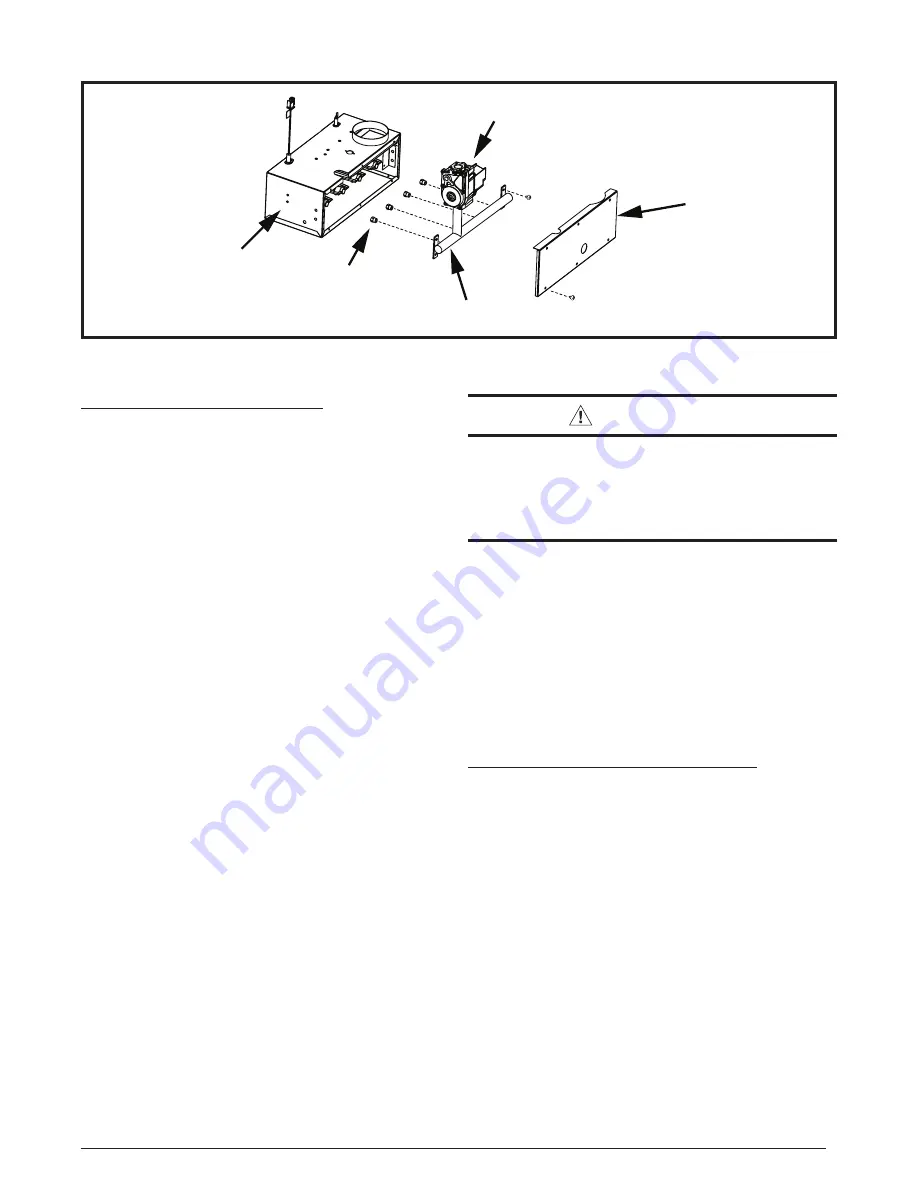

Removing The Burner Orifices

1. Set the thermostat to the OFF position, or its lowest

temperature setting.

2. Shut OFF the gas supply at the manual shutoff valve

located outside of the appliance.

3. Turn off all electrical power to the appliance.

4. Remove the door from the burner box by removing 6

screws.

5. Turn the gas valve ON/OFF knob to the OFF position.

See Figure 14.

6. Remove the wires from the terminals of the gas valve.

7. Remove the supply gas piping from the gas valve inlet.

8. Carefully remove four screws securing the gas manifold

assembly to the burner assembly.

9. Set the screws aside and remove the gas manifold

assembly from the appliance.

10. Carefully remove the burner orifices from the gas

manifold assembly.

11. Read the rating plate affixed to the appliance to

determine its rated input (Btu/hr) and the size of the

factory installed orifices.

IMPORTANT: Before installing an orifice, check

the side or face of the orifice for the drill number

to ensure that it is the appropriate size.

12. Install the appropriate LP/Propane gas burner orifices

into the gas manifold assembly.

NOTE:

The orifices are

included with the furnace.

To prevent cross threading,

hand tighten the orifices into the gas manifold assembly

until snug, then tighten with a wrench.

13. Unscrew the gas valve pressure regulator cap marked

NAT. Invert the cap so LP faces up. Reinstall the cap

and tighten until snug. Make sure LP is visible after

conversion.

Gas Pressure Verification

Measuring the Supply Gas Pressure

1. Turn OFF the gas supply at the manual valve located

on the outside of the unit.

2. Using a 3/16” Allen wrench, remove the plug from the

inlet pressure tap (INLET side of gas valve). See Figure

13 (page 18).

3. Install an 1/8” NPT pipe thread fitting, that is compatible

with a Manometer or similar pressure gauge.

4. Connect the Manometer or pressure gauge to the Inlet

Pressure Tap.

5. Turn ON the main gas supply at the manual valve.

6. Check and adjust the incoming gas line pressure to

11.0-14.0 inches Water Column for LP/Propane gas.

7. Turn OFF the gas supply at the manual valve.

8. Disconnect the Manometer or pressure gauge.

9. Remove the NPT fitting and reinstall the INLET pressure

tap plug. Hand tighten the plug first to prevent cross-

threading. Tighten with 3/16 Allen wrench.

Figure 14. Orifice Removal

Burner Box

Orifice

(X4)

Gas Valve

Gas Manifold

Burner Box

Door

(X4)

(X6)

WARNING:

Do not use Teflon tape or pipe joint compound

on the orifice threads. The hole in the orifice

may become blocked and cause fire, explosion,

property damage, carbon monoxide poisoning,

personal injury, or death.

14. Reinstall the gas manifold assembly to the burner

assembly with the 4 screws, that were removed earlier.

NOTE:

It is important that the center of the orifices

are aligned with the center of the burners.

15. Reinstall the burner box door with the 6 screws that

were removed earlier in step 4.

16. Reconnect the gas piping to the gas valve inlet.

17. Reconnect the wires to the gas valve terminals.