FORM NO. 56043097 / Adgressor

™

/ BR 850S, 850CS, 950S, 950CS, 1050S, 1050CS - 35

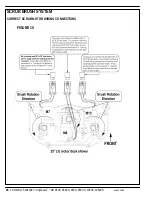

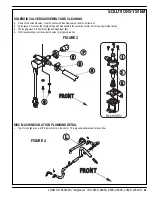

SCRUB BRUSH SYSTEM

FRONT

Belt

Brush

Right Motor

Left Motor

Belt

+

-

BLK

BLUE

CCW Rotation

from shaft end

CCW Rotation

from shaft end

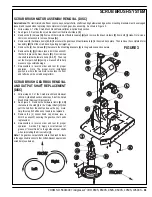

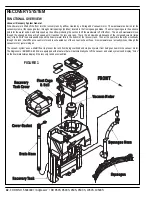

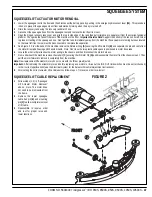

SCRUB BRUSH REMOVAL AND INSTALLATION (CYLINDRICAL)

FIGURE 8

1 Make sure the key switch is off and

disconnect the battery pack before

servicing.

2 To access the brushes, swing open both

the side skirt assemblies. See Figure

6. Note: The skirts are held in place by

Hairpins (AM) on each side, remove the

pins and swing the skirt assemblies out of

the way.

3 Loosen the black knobs (one on each

side) that secure the removable bearing

idler support Plate (AQ) to the brush

housing, then pull the plates down and out

to remove. Grip the scrub brush then pull

and slide it out from the housing end.

4 To install the brush slide it into the housing,

lift slightly, push and turn until it seats into

the drive end assembly.

5 Re-install the idler end plate assemblies,

close the skirt assemblies and secure with

the hairpins.

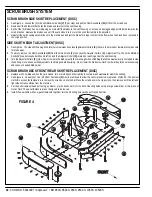

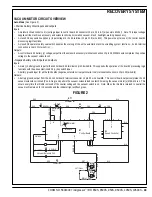

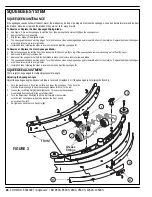

SIDE SKIRT MAINTENANCE & ADJUSTMENT (CYLINDRICAL)

General Overview: The side skirts function is to channel the wastewater to the rear pick-up squeegee, helping contain the water within the machine’s

cleaning path. During normal use the blades will wear in time. The operator will notice a small amount of water leaking out underneath the side

skirts. The skirt height adjustment is automatic on this system using spring tension and movable linkage arms to control the blade pressure. The

side skirt assemblies must move up and down freely for proper operation.

To replace the scrub system side skirts…

•

See Figure 6. Remove the (2) Hairpins (AM) and swing the skirt assemblies open. Remove the (AR) Screws and nuts then remove the skirts

and replace.

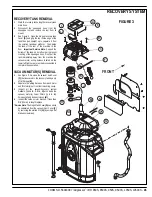

To adjust the scrub system side skirts…

Note: The side skirt blade assemblies have two minor adjustments, they are the individual front collar height and the rear blade pressure spring.

See Figure 9. The Stop Collar (AS) is installed on the pivot hinge bolt to help control the front skirt mount bracket’s travel when the scrub deck is

lowered. It limits the front of the blade from folding (curling) under when scrubbing. Thus allowing the blade to hold its shape better, reduce blade

damage and wear.

A limited amount of adjustment for general blade wear and squeegee wiping performance can be made by reinstalling the spring attachment Screw

(AT) into a different mount hole (A, B or C). This change will increase or decrease the spring force (pressure) pulling down on the rear edge of the

skirt blade. Position “C” creates maximum down pressure on the blade and position “A” is minimum pressure.

FIGURE 9

1/4"

(6.3mm)

AS

AT

A

B

C

Содержание Adgressor BR 1050CS

Страница 74: ...72 FORM NO 56043097 Adgressor BR 850S 850CS 950S 950CS 1050S 1050CS ELECTRICAL SYSTEM Drive Motor Breakdown ...

Страница 81: ......

Страница 82: ...www nilfisk advance com 2006 ...