34 - FORM NO. 56043097 / Adgressor

™

/ BR 850S, 850CS, 950S, 950CS, 1050S, 1050CS

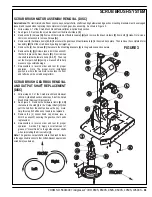

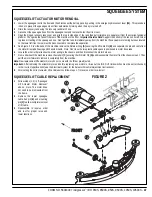

SCRUB BRUSH SYSTEM

AR

FRONT

AQ

AN

AM

AO

AP

AQ

AN

AO

AP

AM

CCW*

CCW*

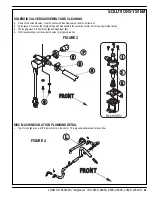

FIGURE 6

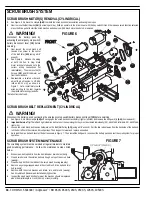

SCRUB BRUSH MOTOR(S) REMOVAL (CYLINDRICAL)

1

See Figure 6. Remove the Hairpin (AM) from both the scrub deck skirt assemblies and swing them open.

2

Next remove the Belt Guards (AN) (4 screws per side). With an operator in the driver’s seat with the key switch ON and the increase scrub function selected

press the drive pedal to start the scrub brushes and observe which brush motor needs to be removed.

WARNING!

Disconnect the battery pack by

activating the emergency stop switch/

battery disconnect lever (13) before

servicing.

3 Next loosen the scrub brush belt

tension Hex screw in the center

of the Belt Idler (AO) (using a 5/8”

wrench).

4

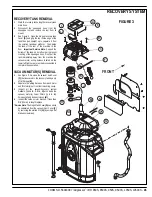

See Figure 8. Remove the wiring

at both the Pos. & Neg. brush

motor terminal studs and note the

correct wiring connections (for

reinstallation). Then remove the (3)

Screws (AP) and lift the motor out

from the scrub deck.

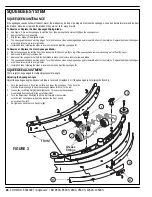

5 Reassemble in reverse order and

adjust the belt tension to 1/2-9/16

inches (13-14 mm) as shown in

Figure 7. Note: Install motors with

wires pointing to the rear towards

the plastic motor wiring standoffs.

* Rotation from shaft end.

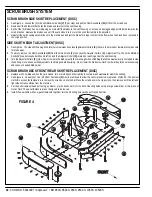

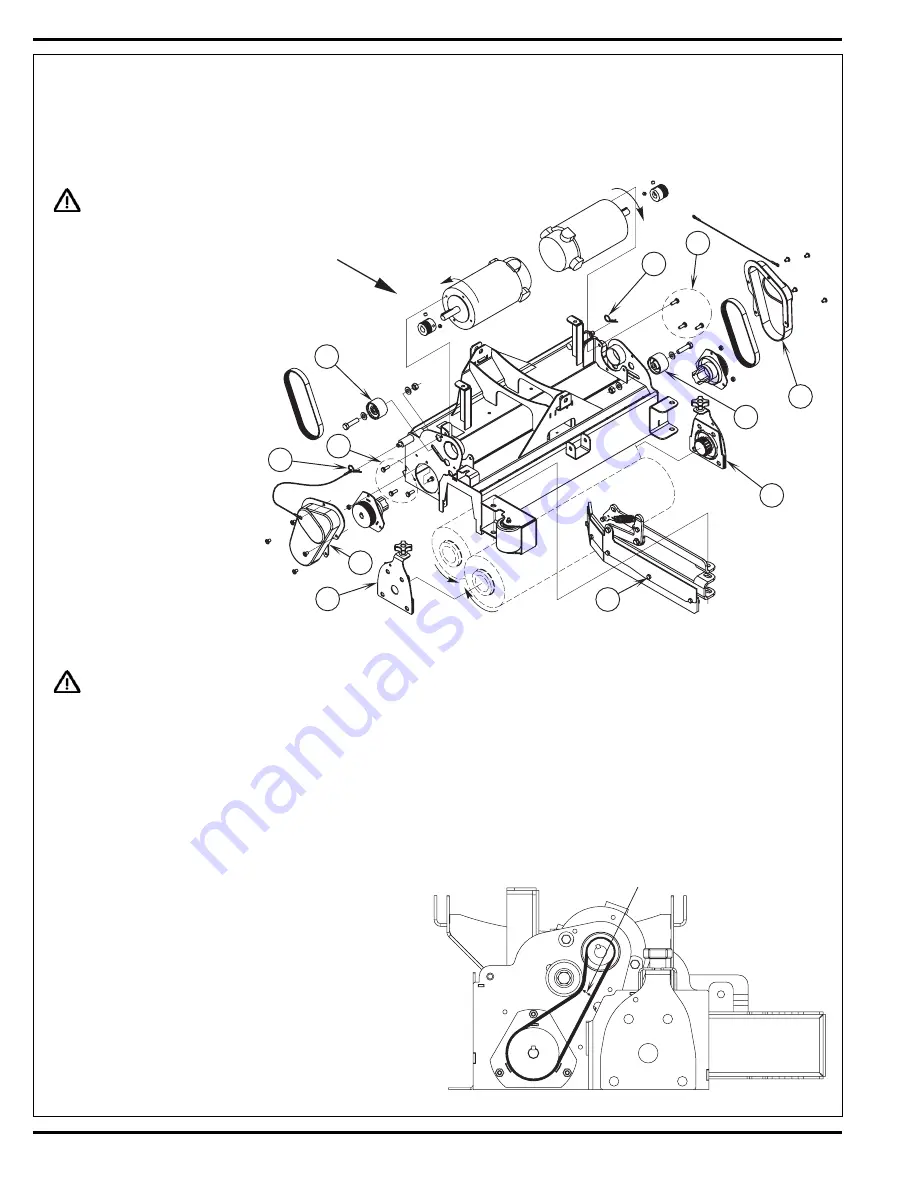

SCRUB BRUSH BELT REPLACEMENT (CYLINDRICAL)

WARNING!

Disconnect the battery pack by activating the emergency stop switch/battery disconnect lever (13) before servicing.

1

See Figure 6. Remove Hairpin (AM) and swing open the scrub deck skirt assembly (right or left side) and remove the belt guard(s) (AN) (4 screws each).

2

Important Service Tip: The left and right side drive belts are not the same lengths they must be ordered individually (P.N. 56407465, left side & P.N. 56407466,

right side).

3

Loosen the scrub brush belt tension hardware on the Belt Idler Pulley (AO) (using a 5/8” wrench). Pull the idler wheel away from the backside of the belt and

roll the belt off both the motor and brush pulleys. Then inspect for wear and replace as needed.

4

Re-install the drive belt and tension the belt as shown in Figure 7. Then install the belt guard, reconnect the battery pack and test the scrub system for proper

operation.

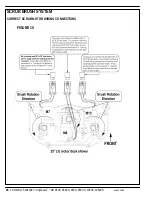

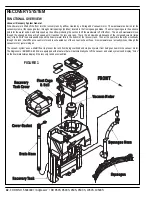

SCRUB BRUSH SYSTEM MAINTENANCE

The scrubbing system must be serviced at regular intervals to maintain

good scrubbing performance. Follow the maintenance steps listed

below.

1

Rinse clean, built up debris from the debris hopper drain holes (daily).

2

Clean drain holes in the solution delivery trough on top of the scrub deck

(weekly).

3

Clean built up dirt from the inside of the scrub brush housing (weekly).

4

Remove any string wrapped around the scrub brush, drive hub and idler

hub (weekly).

5

Remove both the scrub brushes and rotate, turn end for end (weekly).

See Scrub Brush Removal and Installation (Cyl) section.

6

Inspect the scrub brush bristles for wear, the brushes should be replaced

when the bristle length is 1 inch (26 mm) or less (monthly).

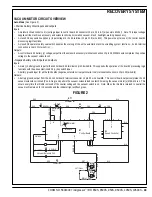

FIGURE 7

1/2" to 9/16" (12-14mm)

Содержание Adgressor BR 1050CS

Страница 74: ...72 FORM NO 56043097 Adgressor BR 850S 850CS 950S 950CS 1050S 1050CS ELECTRICAL SYSTEM Drive Motor Breakdown ...

Страница 81: ......

Страница 82: ...www nilfisk advance com 2006 ...