22 - FORM NO. 56043097 / Adgressor

™

/ BR 850S, 850CS, 950S, 950CS, 1050S, 1050CS

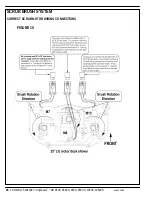

WHEEL DRIVE SYSTEM

FRONT

Yel/Blk

Wire

Red/Grn

Wire

Radius

Radius

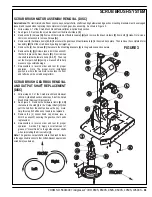

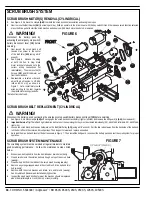

STEERING SPINDLE AND WHEEL DRIVE MOTOR ASSEMBLY REMOVAL

WARNING!

Turn the main key switch (J) to the off position and disconnect the battery pack by pushing in the emergency disconnect lever (13).

Next block both rear wheels so machine can’t roll.

1 See Figure 5. Remove the brake foot pedal (A) secured by the (2) screws (D) that fasten the pedal mount bracket to the chassis allowing

access to the spindle retainer nut.

2 Pull out the brake rod (E) and use a 1-7/16” socket to remove the large spindle nut (F) from its shaft.

3 From underneath the front of the machine remove the (4) (G) screws and push the lower steering column to the rear of the machine. This

is done to separate the chain (H) from the steer sprocket (I). Service Note: Use a 5/8” socket with 3” extension to remove screws and also

correctly position the large hole in the steer plate (J) in order to access the far back left screw.

4 On the right side of the drive motor remove the motor wiring cover and observe the (2) wires (red/green & yellow/black) attached to the motor

terminal connections for reassembling (shown in Figure 4.5). Then remove the wires using a 13mm wrench.

5 Remove the (1) socket head cap screw (use a 3mm hex wrench) that retains the motor wiring harness P-clamp, then pull wiring to the rear of

the machine.

WARNING!

Never work under machine without safety stands or blocking to support the machine.

6

Safely jack up or lift the front of the machine to a height of approximately 16 inches (41 cm) to remove the wheel motor spindle assembly. Place

wood blocking under both front frame legs to support machine when removing the wheel /spindle assembly. Service Note: Be careful not to

damage the threads and bearing surfaces when guiding the spindle shaft down through the frame opening.

7 Inspect bearings and shaft seal and replace as needed.

8 To remove the steer spindle weldment (K) you must remove the steer plate (J) (with splash fender) held by (4) (L) fl at head socket screws (use

a 5mm hex wrench) then separate the brake return spring and lay these removed parts to the side. Next remove the (4) item (M) fl at head

socket screws (55mm length) then fi nish removing the spindle weldment.

9 See

the “Drive Tire Removal” section for further disassembly steps.

10 Re-assemble in reverse order and tighten the spindle shaft nut (F) to 20ft/lbs (27 Nm) to eliminate any bearing play.

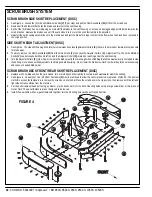

DRIVE TIRE REMOVAL

1 Follow the steps 1-8 in the “Steer Spindle and Wheel Drive Motor Assembly Removal” section.

2 See Figure 5. Remove the socket head cap screw (O) (use a 6mm hex key wrench) that fastens the right side brake lever to the support mount

(N). Then separate the brake lever from the support mount.

3 Carefully separate (tap off) the motor end bell housing (P) from the main motor case. Service Tip: To remove the housing use a brass drift or

piece of hard wood and strike the end bell edge evenly at points 120 degrees apart to slowly work it from the motor bearing.

4 Using a 5mm hex key wrench remove the (8) socket cap screws (Q) that secure the drive tire (R) to the motor drive hub and complete the tire

removal.

5 Install a new drive tire and tighten (torque) the (8) socket cap screws (Q) to 12 Ft/Lbs (16.2 N/M). Service Tip: Apply a small amount of Loctite

242 to all the cap screws to prevent the fasteners from backing out.

6 Re-assemble in reverse order following all the steps outlined in the steer spindle and drive motor removal section.

FIGURE 4.5

Содержание Adgressor BR 1050CS

Страница 74: ...72 FORM NO 56043097 Adgressor BR 850S 850CS 950S 950CS 1050S 1050CS ELECTRICAL SYSTEM Drive Motor Breakdown ...

Страница 81: ......

Страница 82: ...www nilfisk advance com 2006 ...