FORM NO. 56043097 / Adgressor

™

/ BR 850S, 850CS, 950S, 950CS, 1050S, 1050CS - 31

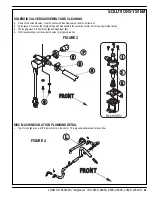

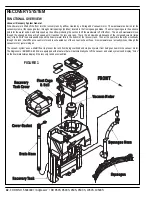

SCRUB BRUSH SYSTEM

FRONT

Right

Left

FRONT

M

L

K

J

I

H

N

O

G

F

P

R

Q

S

T

U

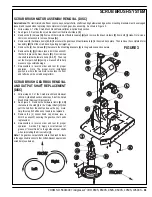

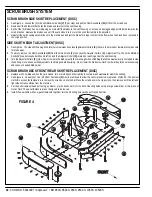

SCRUB BRUSH MOTOR ASSEMBLY REMOVAL (DISC)

Service Note: The items listed; shaft dust covers, keys, output shafts, shaft mounting hardware and gear-box mounting brackets, must be salvaged

(saved) and reused when replacing the complete motor and gear-box assembly. As shown in Figure 3.

1 Follow steps 1-7 of the Scrub Brush Deck Removal (Disc & Cylindrical) section.

2 See Figure 3. Remove the scrub brushes from the Brush Holders (F).

3 Remove the (3) Screws (G) from each thermoid disc (fl exible coupler) (H) and remove the Brush Holders (F) from both (I) Hubs. Note: Use a

13mm socket wrench to remove Screws (G).

4 Remove all (8) hardware items (J & K) that secure the gear case Mount Brackets (L) to the scrub deck plate. Then remove the complete Motor

Assembly (M) from the scrub deck by pulling it straight up.

5 Remove the (8) hex Screws (P) that secure the Mounting Brackets (L) to the gearboxes and separate.

FIGURE 3

6 Remove the (8) (Q) Screws (use a 5mm hex wrench)

that hold in place the Dust Covers (R). Next remove

the shaft retainer hardware items (S & T). Then tap

out the Output Shaft (U) using a brass shaft to help

prevent any possible damage.

7 Re-assemble in reverse order and test for proper

operation. Note: The proper motor installation

position is where the two motor wires face the front

and left side on the scrub deck platform.

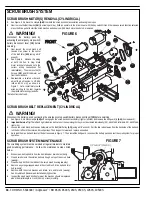

SCRUB BRUSH GEARBOX REMOVAL

AND OUTPUT SHAFT REPLACEMENT

(DISC)

1 Follow steps 1-7 of the Scrub Brush Deck Removal

(Disc & Cylindrical) section and steps 2-6 of the Scrub

Brush Motor Removal (Disc) section.

2 See Figure 3. Remove the hardware items (N & O)

that secure the Hub (I) to the Output Shaft (U) then

pull the hub from the shaft and save the key. Note:

Skip this step if shaft does not need to be replaced.

3 Remove the (4) socket head cap screws (use a

5mm hex wrench) securing the gearbox that needs

replacement.

4 Re-assemble in reverse order and test for proper

operation. Service Tip: Apply a small amount of

grease or “Never Seize” to the gearbox output shafts

when reinstalling the drive Hub(s) (I).

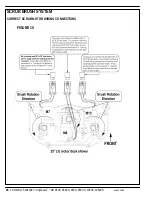

Note: The gearbox output shafts rotate the brush holders

in the opposite direction of other Nilfi sk-Advance automatic

scrubbers (see below).

Содержание Adgressor BR 1050CS

Страница 74: ...72 FORM NO 56043097 Adgressor BR 850S 850CS 950S 950CS 1050S 1050CS ELECTRICAL SYSTEM Drive Motor Breakdown ...

Страница 81: ......

Страница 82: ...www nilfisk advance com 2006 ...