1

Important Notices:

This reverse osmosis system contains replaceable treatment components critical for effective performance. It is the user’s responsibility to,

and the manufacturer strongly recommends that the user, periodically test the product water to verify the system is performing satisfactorily. See the test kit(s)

for sampling instructions. This system is acceptable for treatment of influent concentrations of no more than 27 mg/L nitrate and 3 mg/L nitrite in combination

measured as N and is certified for nitrate/nitrite reduction only for water supplies with a pressure of 280 kPa (40 psig) or greater.

This system conforms to NSF/ANSI Standard 58 for pentavalent arsenic reduction. See the Performance Data Sheet and Arsenic Facts section for an explanation

of reduction performance.

DO NOT USE WITH WATER THAT IS MICROBIOLOGICALLY UNSAFE OR OF UNKNOWN QUALITY, WITHOUT ADEQUATE DISINFECTION BEFORE OR AFTER THE SYSTEM.

Systems certified for cyst reduction may be used on disinfected water that may contain filterable cysts.

TABLE OF CONTENTS

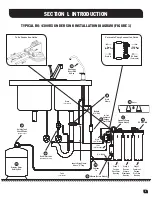

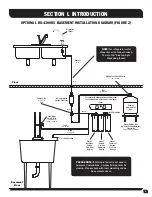

Section I. Introduction

.....................................................................................2

Section II. Specifications

..................................................................................5

Section III. Preparation

......................................................................................6

A. Major System Components.............................................................6

B. Tools Recommended For Installation..............................................6

C. Site Selection For Major System Components.................................7

Section IV. Installation Steps

............................................................................8

A. Faucet Installation.........................................................................9

B. Drilling A Stainless Steel Sink........................................................9

C. Drilling A Porcelain Or Cast Iron Sink..............................................9

D. Prepare the R.O. Air Gap Faucet, Feed Water Supply Hose

And Drain Clamp Assemblies..........................................................9

E. Position the Drinking Water Holding Tank

And Final Connections.................................................................12

F. Start Up.......................................................................................13

Section V. Operation And Maintenance

..........................................................14

A. Normal Operation........................................................................14

B. Changing Filters..........................................................................15

C. Changing The In–Line Activated Carbon Post-Filter........................15

Section VI. Deluxe Component Installation

......................................................16

Section VII. Trouble Shooting Guide

.................................................................17

Exploded View And Parts List

..................................................................................................19

NeoLogic Filtration Products Limited Warranty

......................................................................21