CT34002a_e.doc / Nov-15

Page 10 / 42

4.

Functional description

4.1.

Principle of operation

When a cutting process needs synchronous circumferential speed of the cutting tool with the

line, the only length that can be cut is the one corresponding to the circumference of the cutting

roll (at constant rotational speed). Change of the cutting length needs exchange of the cutting

roll against another one with appropriate diameter.

The CT340 and CT641 controllers use a two-speed principle featuring full synchronism while

the cut is in progress, but taking a different roll speed when the tool is outside the cutting zone

(where synchronism is not necessary). So, in terms of one revolution of the roll, we are talking

about two speed zones: The “synchronous cutting zone“ (which is register settable) and the

“asynchronous zone“ where the roll follows a speed profile calculated in order to get the

desired cutting length. The speed profile of the “asynchronous zone“ is calculated in a way that

the physically possible minimum of acceleration and deceleration torque is applied to the drive

with respect to actual line speed and preset cutting length.

All speed transitions use self-optimizing S-shape profiles for minimum wear and tear of all

mechanical parts, unless a linear ramp form has specifically been selected by corresponding

parameter setting.

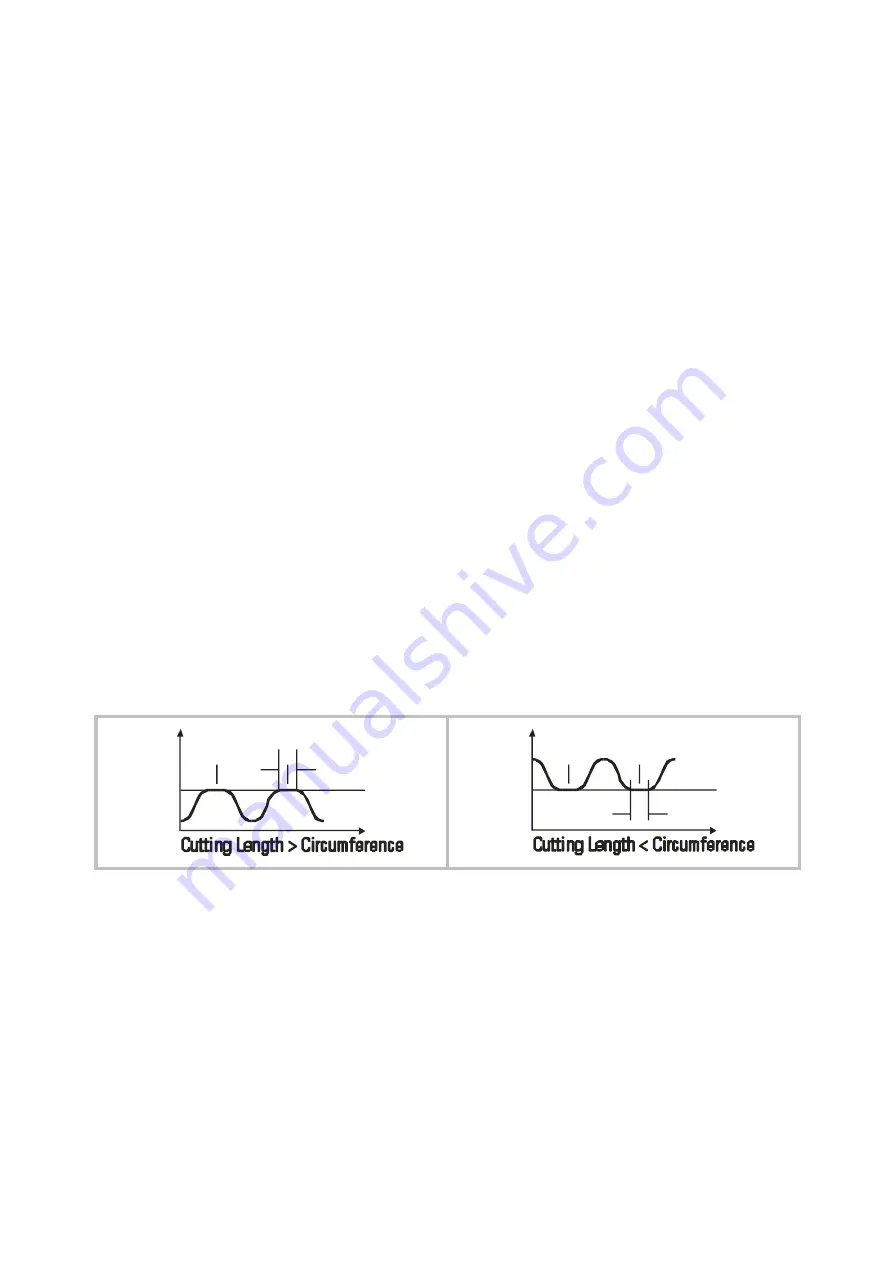

With length settings smaller than the roll circumference, the “asynchronous zone” will take

higher speeds than the “synchronous zone”. With length settings longer than the

circumference, the asynchronous speed will be lower and the drive can even go to a temporary

standstill if necessary. The figure below shows two typical speed profiles:

Cut

V

Line

Sync Zone

t

Cut

V

Line

Sync Zone

t

Continuous closed loop control of the relative roll position with respect to the length progress

of the line, combined with a short update time provide best cutting accuracy and exceptional

smooth motion of the cutting roll at any time.

It is a must to use a 4-quadrant drive or a servo drive for the cutting roll, because the CT340 /

CT641 must be able to accelerate and decelerate the roll under real closed loop conditions.

However, no special requirements are necessary for the line drive for full performance.