Trouble Shooting

AutoCreaser Pro 33A

l

Check that the air distribution has been correctly set.

l

Check that the air separation has been set high enough to feed the sheets.

l

For heavy stocks, very small or very large sheets, embossed or even irregular stock,

it may be required to feed the sheets manually - see page 25 for instructions.

Machine not counting

Open the exit and remove the blade set

(see pages 34-35) to access the dual

sensor post located in between the drive

rollers. Using a soft brush, clean the

visible sensor on the end of the post.

Use the brush to clean the sensors

between the post and the bottom paper

guide which are not visible.

Fig.16 shows the dual sensor

post containing the sensors.

Paper jammed under paper gate.

If paper gets jammed under the paper gate the vacuum drum will stop rotating, this is a

safety feature. Remove the paper and re-adjust the paper gate.

FIG. 16

Page 40

CREASING

Error Screens

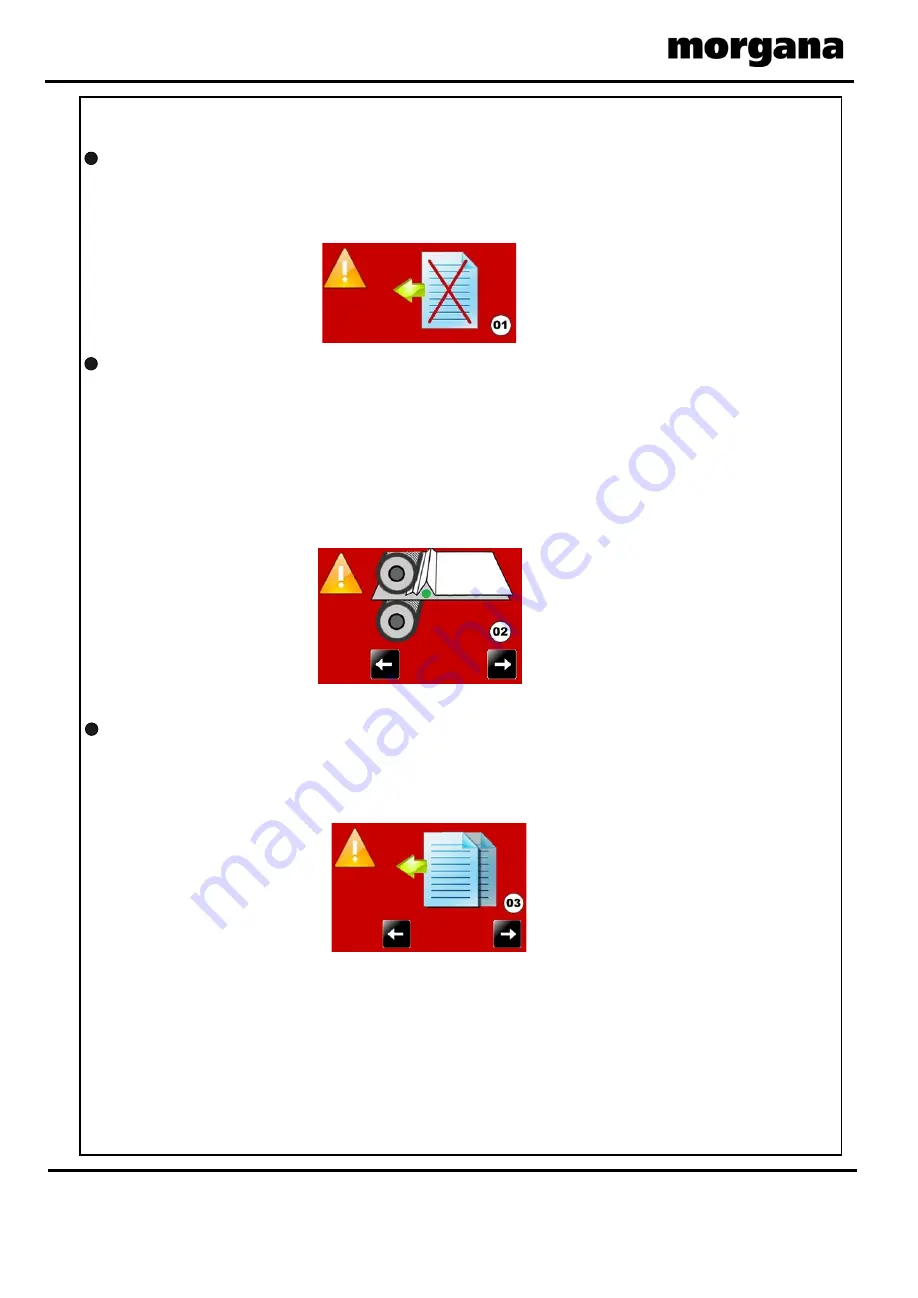

Sheet did not arrive.

If the machine stops and error message 01 is displayed on the touch screen, this

indicates that the paper did not arrive at the end of the suck process; so the machine

timed out. Press the green tick button and then press the start button.

Paper Crunch

If the machine stops and error message 02 is displayed on the touch screen, this

indicates that a paper jam has been detected.

Press the system switch down and then select the right or left arrows, to inch the

paper forwards or backwards. See page 27 that describes how to remove paper jams.

Press the green tick button and then press the start button.

This error message could also mean that the crunch sensors are faulty or need

cleaning.

Double Sheet Feed

If the machine stops and error message 03 is displayed on the touch screen, this

indicates that a double sheet feed has been detected. Check that the paper gate has

been set correctly. Press the green tick button and then press the start button.

Trouble Shooting

Page 41

SYSTEM

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920