Start Up

G : Turbine – Operating Instructions

1) Mechanical

•

Use the 1000 RPM power take-off

•

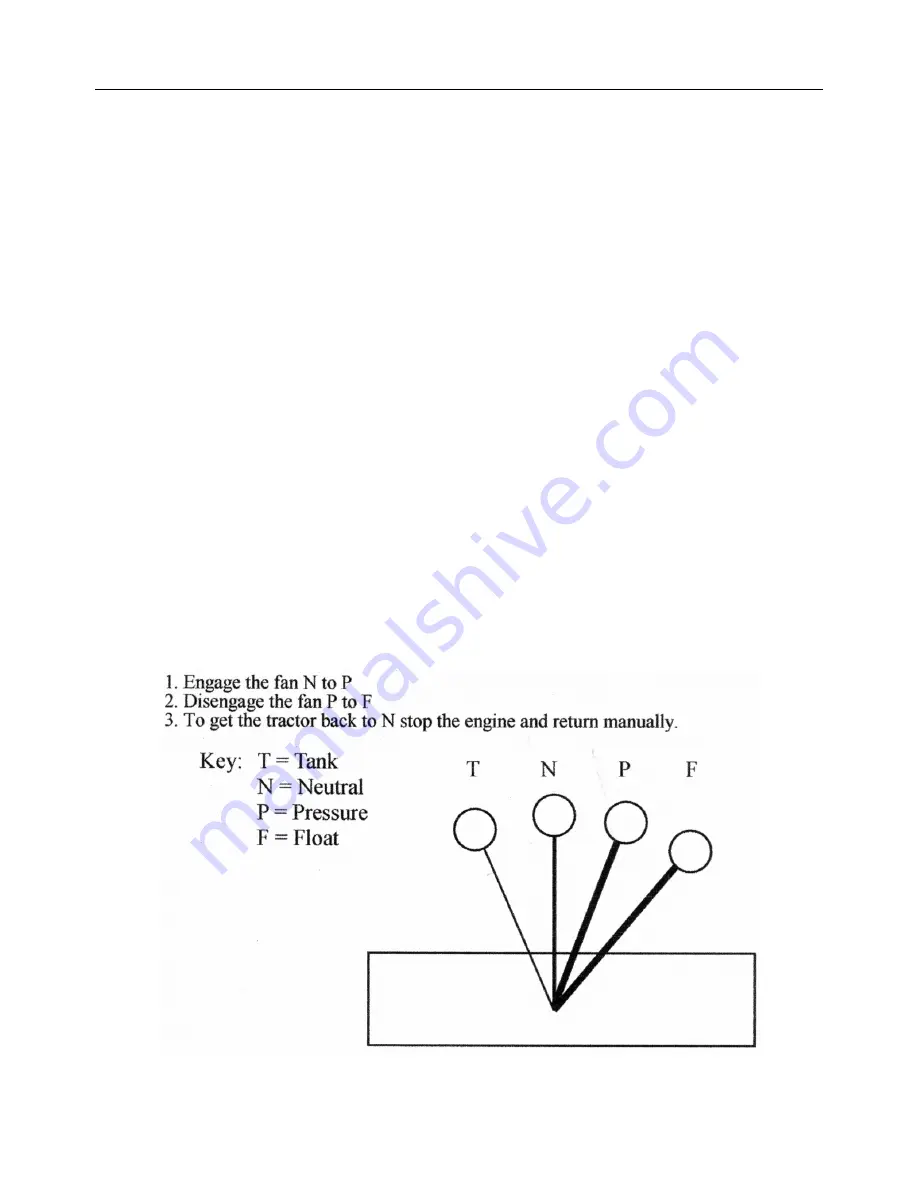

Maintain tractor engine rate during work

•

Do not engage the PTO on full load

2) Hydraulic

a) Specification

Warning and reminder: a number of checks need to be made on the tractor when using the hydraulic turbine

drive system. Consult your dealer.

1) The minimum oil flow rate required at working RPM is 30 liters/min

2) The oil pressure rises to 180 bars on start-up

3)

Feedback must imperatively be below 15 bar; otherwise extensive damage will be caused to

the hydraulic motor. If possible always try to run the oil back into the tractor, without any

restriction, i.e. put the return pipe for the hydraulic fan motor directly into the back of the

tractor without going through the spool valve.

4) When using a tractor with open center hydraulics, use the oil flow regulator on the tractor to control

the speed of the fan and

free flow the oil back to tank

. If there is no flow regulator on the tractor,

an inline flow regulator will be required for the motor, again free flow back to tank.

5) When using a tractor with closed center hydraulics (John Deere) use a Series 3 SCV valve (motor

Spool). If this is not fitted refer to your John Deere Dealer

6) When using the spool lever to control the hydraulic fan consider the points listed below.

Failure to disengage the fan through the float facility on the spool lever, will ‘dead head’ the hydraulic motor,

this may then destroy the manometer or damage the fan motor seals.

18

Содержание Tandem Uni-Drill DP400A

Страница 9: ...Safety Regulations Safety Stickers 9 ...

Страница 17: ...Start Up G TURBINE 17 ...

Страница 23: ...Settings A Distribution Settings 23 ...

Страница 32: ...Settings H Tramline Track Width 32 ...

Страница 41: ...Flow Rate Tables Calibration Procedure 41 ...

Страница 42: ...Flow Rate Tables Calibration Procedure 42 ...

Страница 43: ...Flow Rate Tables Calibration Procedure 43 ...

Страница 44: ...Flow Rate Tables Calibration Procedure 44 ...

Страница 45: ...Flow Rate Tables Calibration Procedure 45 ...

Страница 48: ...DP400A and DP600A Parts booklet 2002 seeding line ...

Страница 52: ...2002 DP600A markers ...

Страница 54: ...Marker Circuit Diagram ...

Страница 55: ...W Seed box hopper extension ...

Страница 56: ...W Seed box Peg Wheels ...

Страница 57: ...W Seed box Distributor Assembly ...

Страница 58: ...W Seed box Distributor Assembly ...

Страница 59: ...W Seed box Variator Assembly W Seed box Variator Assembly ...

Страница 60: ...W Seed box half width shut off ...

Страница 61: ...W Seed box Venturi System ...

Страница 62: ...W Seed box Drive Wheel Assy ...

Страница 63: ...W Seed box Wind turbine Assy ...

Страница 64: ...W Seed box Air Intake ...

Страница 65: ...W Seed box RDS system ...

Страница 66: ...W Seed box MS Variable seeding ...