56

MCP15-500.9

Hot Water Heat Coil Maintenance

If the unit is supplied with a factory installed hot water heat coil,

check the following:

1. Periodically, inspect the coils for signs of corrosion and

leaks. Repair and replacement of the coil and the

connecting piping, valves, etc., must be performed as

needed by a qualified technician.

2. For cleaning the external surface of the coil and fins

with compressed air and/or vacuum:

The coil can

remain in the unit or be removed. Use compressed air

blown into the leaving air side of the coil and/or vacuum

from the entering air side of the coil to avoid pushing

foreign material further into the coil.

3. For cleaning the external surface of the coil and fins

with a cleaning solution:

The coil must be removed from

the unit. Caution should be exercised in selecting the

cleaning solution as well as the cleaning equipment.

Improper selection can result in damage to the coil and/or

health hazards. Cleaning solutions must not be corrosive or

cause damage to copper tube/aluminum fin coils. Be sure

to carefully read and follow the cleaning fluid

manufacturer’s recommendations before using any

cleaning fluid.

4. Maintain the circulated fluid free of sediment, corrosive

products and biological contaminants. Periodic testing of

the fluid followed by any necessary corrective measures

along with maintaining adequate fluid velocities and proper

filtering of the fluid is required.

Hot Water Freeze Stat

If the unit is supplied with a factory installed hot water coil

freeze stat, check the following:

1. Disconnect the control wiring from the freeze stat terminals.

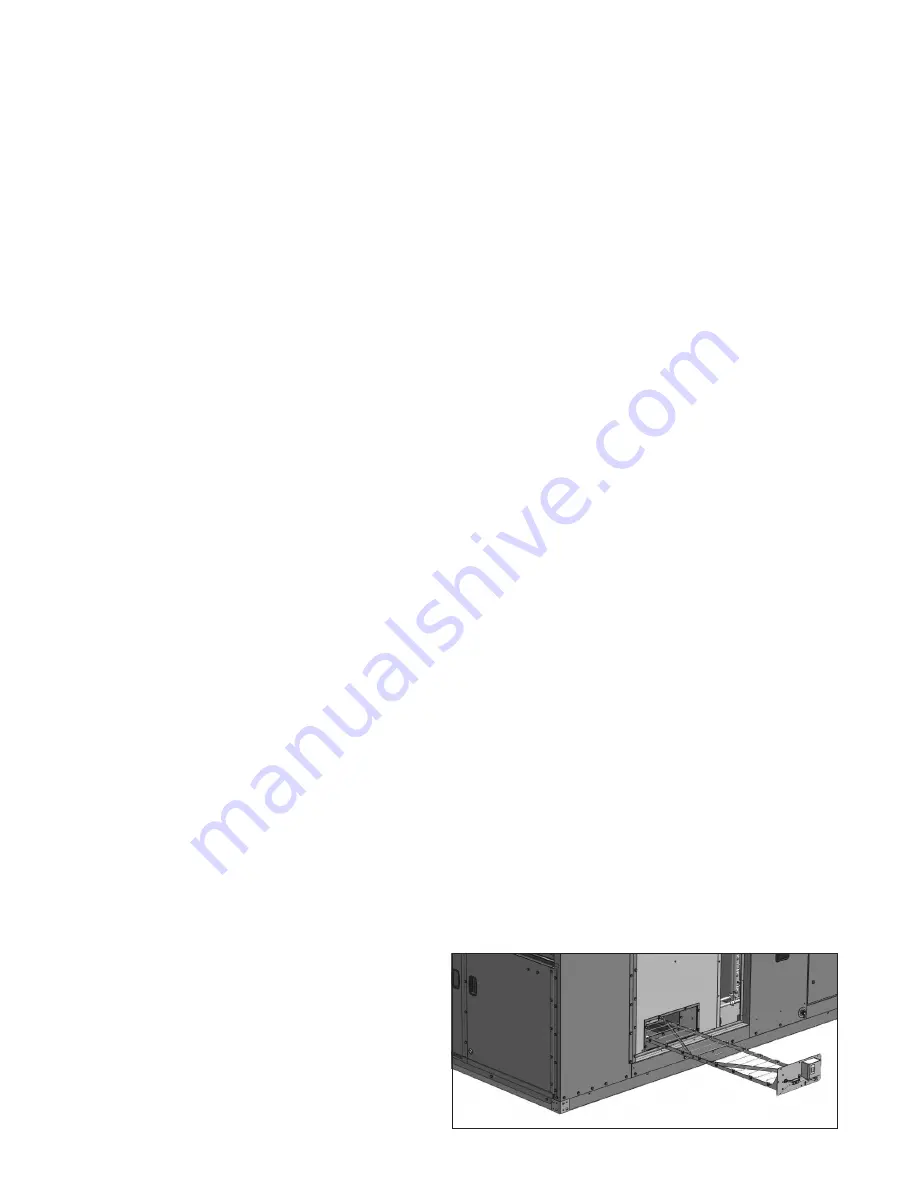

2. Remove the screws holding the freeze stat side access

panel. Refer to Figure 56.1.

3. Slide the freeze stat assembly out.

4. Examine the freeze stat capilary for cleanliness and/or

obstructions as necessary. Ensure the capillary has no

kinks or breaks (replace if either of these conditions is

present).

5. Replace the freeze stat assembly in reverse order. In

replacing the assembly, be certain that the capillary support

frame is properly located and supported. Do not force the

side access panel. It will not fit if the frame is not properly

aligned.

6. Reconnect the control wiring to the freeze stat terminals.

Figure 56.1 - Optional Factory Installed Hot Water

Coil Freeze Stat

MAINTENANCE - CONTINUED

Duct Furnace

When providing annual maintenance for the duct furnace, keep

the unit free from dust, dirt, grease and foreign matter. Pay

particular attention to:

1. The power exhauster discharge opening and the

combustion air inlet louvers.

2. The main burner orifices (avoid the use of hard, sharp

instruments capable of damaging surfaces for cleaning

these orifices). To check the main burner orifices, see

Manifold Assembly Removal section below.

3. The heat exchanger should be checked annually for cracks.

If a crack is detected, the heat exchanger should be

replaced before the unit is put back into service.

4. The gas valves and piping should be checked annually for

general cleanliness and tightness.

5. The gas controls should be checked to ensure that the unit

is operating properly.

6. If equipped with the standard efficiency (81%) gas heat

option:

a. Inspect and clean the condensate drain tray located

under the heat exchanger tube openings.

b. Inspect and clean the condensate drain tubes located on

the end of the drain tray that are routed to the outside of

the cabinet. Ensure that the tubes are not kinked or

blocked.

7. If equipped with the hybrid efficiency (D-Cabinet only) or

high efficiency (90% or 94%) gas heat option:

a. Inspect and clean the condensate drain trap and piping.

b. Fill the trap with water to ensure proper operation.

c. If a condensate neutralizer tube is installed, recharge per

the neutralizer tube manufacturer’s instructions.

d. Check the condensate overflow switch for cleanliness

and proper operation.

Manifold Assembly Removal

1. Shut off gas and electric supply.

2. Open the duct furnace control access compartment doors.

3. Disconnect gas manifold at ground union joint.

4. Remove the screws holding the manifold to the heat

exchanger support.

5. Slide the manifold through the manifold bracket.

6. Clean the orifices as necessary.

7. Slide the manifold back into the manifold bracket and

reinstall the screws that hold the manifold to the heat

exchanger support.

8. Reconnect the gas line to the manifold at the ground joint

union.

9. Turn on the electric and gas supply.

10. Check the ground union joint for leaks with a soap solution.

Tighten if necessary.

11. Close the duct furnace control access compartment doors.

Содержание MPR Series

Страница 17: ...17 MCP15 500 9 PAGE INTENTIONALLY LEFT BLANK ...

Страница 67: ...67 MCP15 500 9 PAGE INTENTIONALLY LEFT BLANK ...