MODEL 250DP DUAL PULSE

RESISTANCE WELDING POWER SUPPLY

990-280

2-1

CHAPTER 2

INSTALLATION

Location

Install the 250DP in a well-ventilated area that is free from dirt and moisture. Allow sufficient clearance

around the sides and rear of the unit so that cooling air may flow properly. Position the 250DP as close as

practical to the weld head.

Power Line

CAUTION:

Do not connect the line cord at this time.

This power supply was wired for the specific input line voltage marked on the line cord at the factory. The

standard 250DP is wired for 115 VAC. Reconnection for operation at another voltage may be made by a

qualified technician. Refer to Chapter 7 under

Modifications and Calibration.

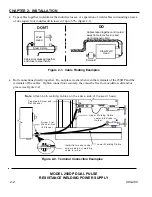

Welding Cables

Position the 250DP on the work bench approximately 5 inches behind the weld head. Use the cables

furnished with the weld head to connect the terminals on the back of the weld head to the appropriate

terminals on the front of the 250DP. Convention is to connect the lower electrode of the weld head or hand-

piece to the (+) output terminal and the upper electrode to the ( - ) output terminal of the 250DP. If the weld

head cables are unserviceable, use the following criteria in selecting new cables:

x

Use No. 2 AWG welding cables, or No. 2/0 AWG welding cables if the cables are more than 12 inches

long. The diameter of the cables should be as large as practical.

x

Use the shortest possible welding cables. It is not uncommon to have losses up to 50% per foot for No.

6 cable and 20% for No. 2 cable.

To reduce energy losses, follow these recommendations:

x

Route cables so that they do not surround magnetic materials such as air solenoids, tooling, or steel weld

heads (see figure 2-1).