56

IOMM ACZ/AGZ-1

DISPLAYS, SYMBOLS, KEYS, AND BUTTONS

The Zone Terminal simultaneously displays three set points or sensed values. In addition, flashing

symbols indicate when items are in a state of alarm. The keys, buttons, displays, and symbols are

explained below.

Table 20, Displays, Symbols, Keys, Buttons

DISPLAYS, SYMBOLS,

KEYS, BUTTONS

DESCRIPTION

Display Button

1, 2, 3

Select the value you want to monitor or

adjust.

Enter Key

Use to commit your changes.

Adjustments are not processed unless

you press Enter.

Flashing Numbers

Appear in Display 1, 2, or 3 to indicate

numbers you can adjust. Numbers that

do not flash are monitor only numbers.

Flashing

s

s

,

m

m

, ( | )

Shows an item is in alarm.

Mode Selector Button

Press this button to select Operating

Modes: Monitor, Adjust, Password, Time

Scheduling. A green Mode Indicator light

moves through the modes.

On/Off Status Symbols( | )

for On/a circle (

m

m

) for Off

Observe On/Off conditions of a point in

the HVAC controller with these symbols.

A bar (| ) for On, a circle (

m

m

) for Off.

These are always monitor only items. If

the symbol flashes, item is in alarm.

Red Alarm Light

Flashes anytime a problem exists

regardless of which Operating Mode you

have entered.

Up (

↑

↑

) or Down (

↓

↓

) Arrow

Keys

Use these keys to adjust a flashing

number.

l

l

Appears in the displays, and corresponds

to the item you are monitoring or

adjusting.

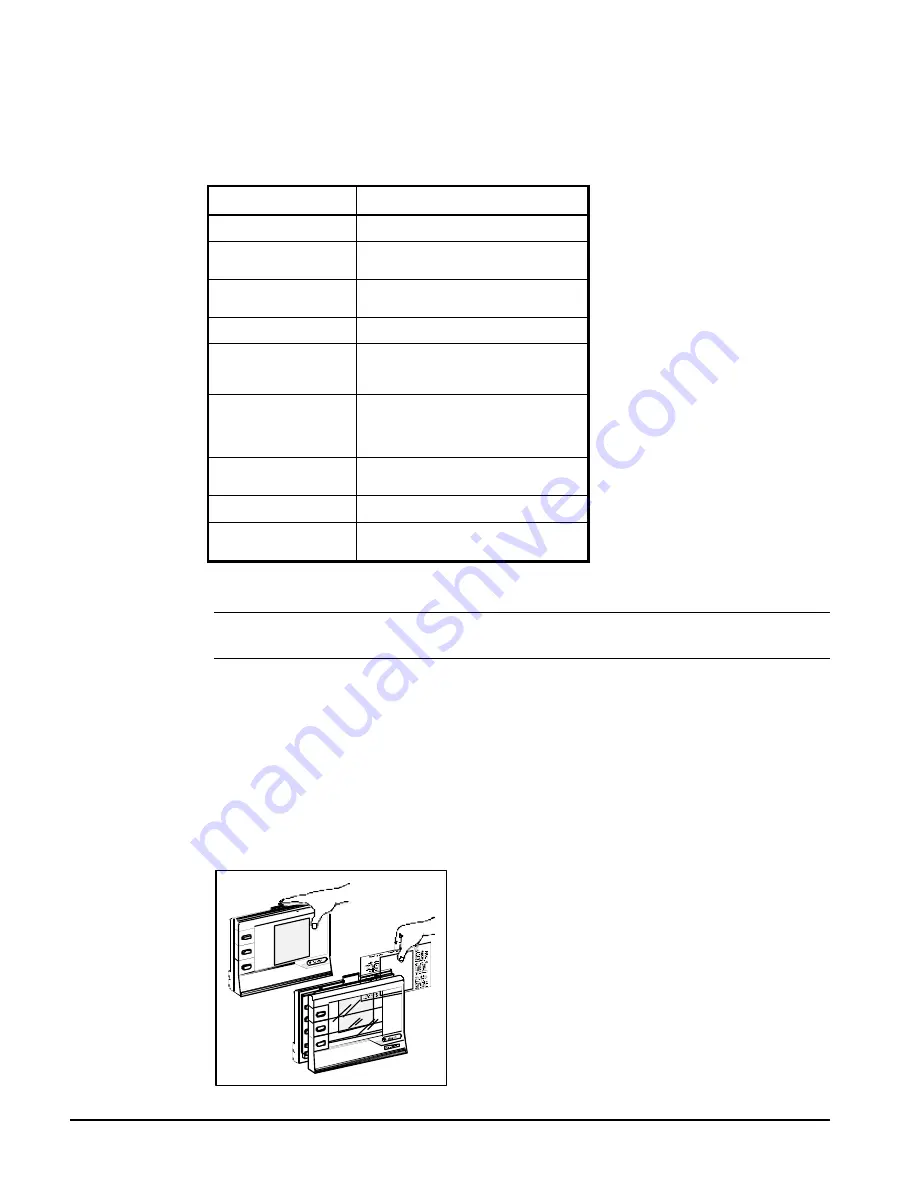

INSTALLING THE PLASTIC LABELS

Note:

The insert is normally factory-installed. These steps are required only if the insert is not

already installed.

To use the ZT, you'll need the plastic label which is included with your ZT.

Insert

The clear plastic Insert is a custom-made label unique to your chiller. Use this Insert when monitoring

or adjusting specific items of your system:

1.

With the ZT on a flat surface, press the white tab with your index finger (Figure 27).

2.

Pull the front cover of the ZT away from the back and slide the Insert into position.

3.

Press the ZT together. With the Insert in place and the ZT connected, the

l

in the top position of

each display lines up with the first word.

Figure 27, Installing the Insert

Содержание ACZ 045A

Страница 6: ...6 IOMM ACZ AGZ 1 Figure 3 Clearance Requirements...

Страница 27: ...IOMM ACZ AGZ 1 27 Figure 12 AGZ AM Single point Connection with FanTrol...

Страница 28: ...28 IOMM ACZ AGZ 1 Figure 13 AGZ AM Single point Connection with SpeedTrol...

Страница 29: ...IOMM ACZ AGZ 1 29 Figure 14 AGZ AM Unit Control Schematic UNT...

Страница 30: ...30 IOMM ACZ AGZ 1 Figure 15 AGZ AM Staging Schematic UNT...

Страница 31: ...IOMM ACZ AGZ 1 31 Figure 16 AGZ AM MicroTech Controller Schematic...

Страница 32: ...32 IOMM ACZ AGZ 1 Figure 17 AGZ AM Unit Control Schematic MicroTech...

Страница 33: ...IOMM ACZ AGZ 1 33 Figure 18 AGZ AM Staging Schematic MicroTech...

Страница 34: ...34 IOMM ACZ AGZ 1 Figure 19 ACZ Field Connection Diagram No Capacity Control...

Страница 35: ...IOMM ACZ AGZ 1 35 Figure 20 ACZ Field Wiring Diagram Capacity Control Staging...

Страница 104: ...Post Office Box 2510 Staunton Virginia 24402 2510 USA 800 432 1342 www mcquay com...