39

39

39

39

Inspect each part at the timing shown in the table below.

Caution

Inspection Item List

Inspection location

Inspection item

Inspection/

replacement timing

Inspection method

Servicing method

Mounting bolt/nut

Looseness

Before start of work

Refer to page 40.

Contact the dealer.

Securely tighten.

Whenever looseness is

found, or every year

Refer to page 40.

Contact the dealer.

Spray pump

Dirty oil in the crank case

Before start of work

Visual check

Refer to page 40..

Leakage of oil from the crank case Before start of work

Visual check

Contact the dealer.

Oil level in the crank case

Before start of work

Visual check

Refer to page 40..

Change oil in the crank case

Every 100 hours (*1)

-

Refer to page 40..

Add to the lubrication locations.

Every 100 hours

Refer to page 40..

Refer to page 40..

Rattling/loose input shaft

Before start of work

Refer to page 40..

Contact the dealer.

Add grease to the input shaft.

When the universal joint

is installed

Refer to page 40..

Refer to page 40..

Water filter net

Clean.

Before start of work

Refer to page 40..

Refer to page 40..

Strainer

Clean.

Before start of work

Refer to page 40..

Refer to page 40..

Line filter

Clean.

Before start of work

Refer to page 40..

Refer to page 40..

Chemical piping

connection parts

Looseness

Before start of work

Refer to page 41..

Refer to page 41..

Leakage

Before start of work

Refer to page 41..

Contact the dealer.

Nozzle

Clogging

Before start of work

Refer to page 41..

Contact the dealer.

Replace

Replace every 100

hours (rough guide).*2

-

Contact the dealer.

Jet nozzle

Clogging

Before start of work

Refer to page 41..

Contact the dealer.

Replace

Replace every 100

hours (rough guide).*2

-

Contact the dealer.

V-belt

Looseness

Every 100 hours (*1)

Refer to page 41..

Refer to page 41..

Damage

Before start of work

Visual check

Contact the dealer.

Fan transmission

Leakage of oil

At start of work

Visual check

Contact the dealer.

Change oil.

Every 600 hours (*1)

-

Refer to page 41..

Tire

Air pressure

Before start of work

Refer to page 42..

Refer to page 42..

Cracks and damage

Before start of work

Visual check

Contact the dealer.

Wear

Before start of work

Visual check

Contact the dealer.

Foreign deposits

Before start of work

Visual check

Remove.

Wheel

Loose wheel nut

Every 100 hours (*1)

Visually check and

touch by hand.

Contact the dealer.

Damaged rim

Before start of work

Visual check

Contact the dealer.

Axle

Loose fixing bolt

Every 100 hours (*1)

Visually check and

touch by hand.

Contact the dealer.

*1 --- Check after 50 hours only for the first time.

*2 --- Even before the replacement timing arrives, replacement may be required if any of the following

symptoms is found:

• The pressure does not rise.

• Clogging occurs and persists after cleaning.

• The spray pattern is disturbed.

16

16

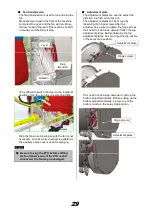

Maintenance and Inspection

●

Perform inspection/servicing with the tractor-trailed sprayer installed on the tractor and also with

the stand erected.

●

Stop the tractor engine and remove the key before performing maintenance/inspection.

●

If any inspection or servicing item requires the tractor engine to remain running, do not perform

such item on your own, but always contact the service personnel at your Maruyama dealer instead.

●

Dispose of oils, etc., properly.

Содержание SSD600

Страница 1: ...Operation Manual Tractor trailed Sprayer Please Read This Document Before Use SSD600...

Страница 17: ...16 16 16 16...

Страница 18: ...17 17 17 17...

Страница 49: ...48 48 48 48 MEMO...

Страница 50: ...49 49 49 49 MEMO...