USE AND MAINTENANCE MANUAL

– DLC

NET

Series

Settings

LOGIC S.r.l. - M0145Db.docx

Mod. L0006A01 of 30/05/2016

Page 40 of 78

4.2 Fieldbus communication

4.2.1

PLC hardware setting

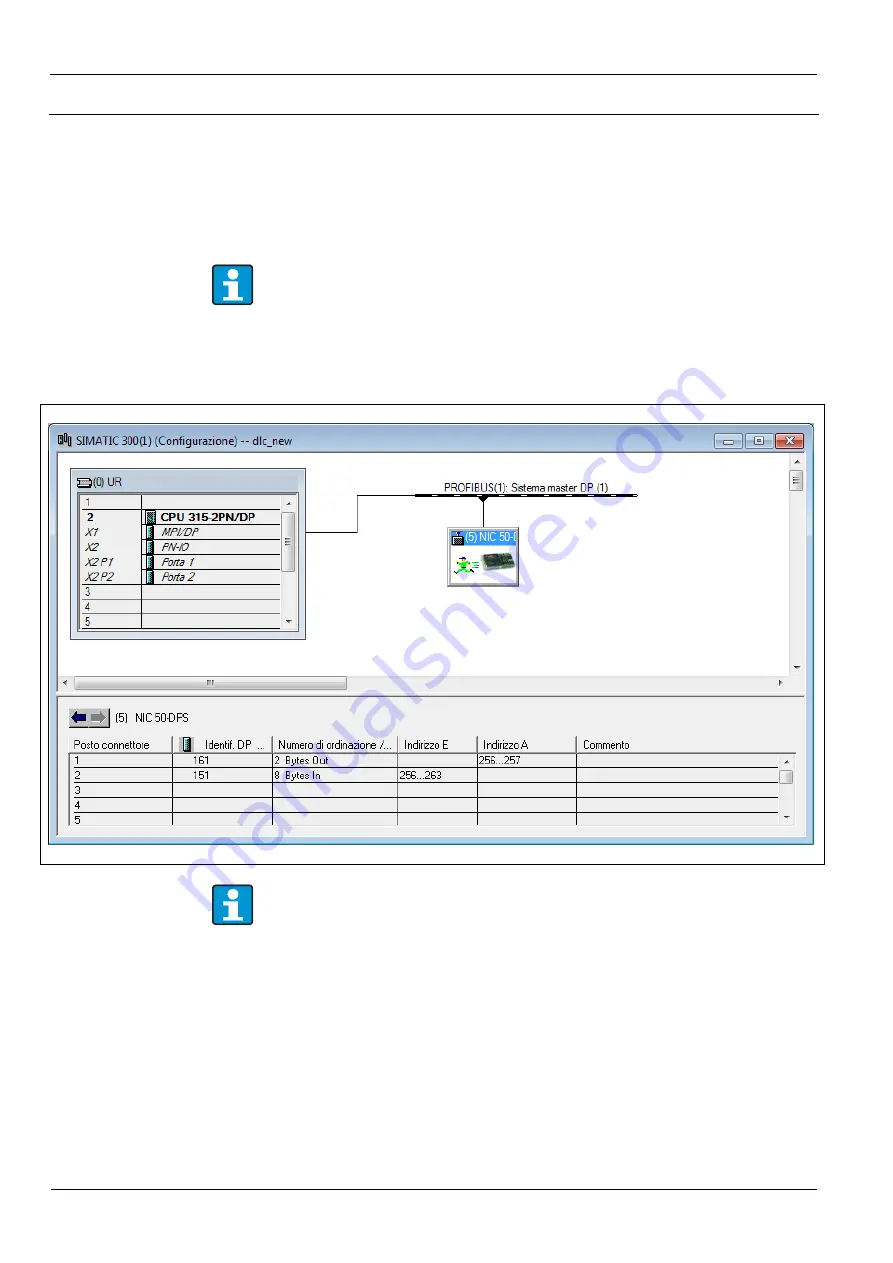

The shared data structure is the same for both versions of the Fieldbus. It consists

of a total of 2 input bytes from PLC and 8 output bytes to the PLC.

Then, the hardware configuration made in the PLC software will have 2 output

bytes and 8 input bytes.

In the PLC hardware configuration always put before 2 bytes of output to 8

bytes of input. Otherwise you cannot establish communication.

Figure 31 shows an example of hardware configuration for Siemens PLC in

Simatic Step 7

®

development environment.

Figure 31. Hardware setting for Siemens PLC

For the supply of the GSD library files for Profibus-DP

®

Protocol and GSDML

for Profinet

®

contact the customer service Logic.

4.2.2

Data structure

Looking at the PLC side, the data structure provides 2 output bytes and 8 bytes of

input. Especially, you can read the data weight from the instrument in 32-bit

format, a diagnostic word and stable weight threshold currently set, also

expressed as a 16bit word. The 2 output bytes are used to set within the

instrument a new value of the stable weight threshold.

The exact meaning of each data exchanged is described in Table 22.