21

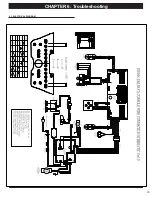

CHaPTer 6: Troubleshooting

6.6 TrOUBLeSHOOTiNG - NOiSe iSSUeS

NOiSe iSSUeS

1) SYMPTOM:

a. Thumping noise twice per rotation on new machine.

b. Rubbing / grinding noise.

c. High pitched “bell-like” sound from under the motor cover.

d. Banging or clunking sound.

e. Slapping / thunking / squeaking sound with each footstep.

f. Rubbing sound underneath the treadmill.

g. Squeaking noise when raising / lowering the deck into storage positions.

h. Squeaking / grinding noise when using elevation.

2) SOLUTION:

a. This noise is from the roller or running belt.

- If this is a new unit, some noise is normal as the running belt forms around the rollers.

- Check that the belt is centered and tensioned correctly (see Section 3.2).

- Check the rollers for excess wax build up. Remove and clean the rollers if needed.

- Replace the rollers or running belt as needed.

b. This sound is likely a moving component.

- Remove the motor cover and check the drive belt for alignment and make sure it is not slipping or is frayed / cut in any way. Replace the

drive belt if needed.

- Make sure the optic disk on the motor is not rubbing the speed sensor.

- Turn the motor by hand to see if motor brushes or bearings are rubbing. Replace the motor if needed.

- Check the front and rear rollers, replace if needed.

c. This sound is likely caused by the optic disk.

- Check that the optic disk is tight on the motor and not rubbing the speed sensor.

d. The sound is likely due to the unit not being level.

- Check that all levelers are touching the ground.

- Move the treadmill to another flat surface.

e. This sound is from the running deck / belt.

- Check that the running deck is tightly attached to the frame.

- Check the deck shocks for detioration or crumbling. Replace if needed.

- Check to see if the air shock is making this noise, lubricate or replace if needed.

f. This sound is likely due to the air shock.

- Lubricate or replace the air shock as needed.

g. This sound is likely from the incline motor.

- Check that the incline motor connection points include Teflon washers.

- Lubricate the incline motor worm screw and connection points with grease.

- Replace the incline motor.