Installation

18

Hydro Kit

Cut the pipes and the cable

- Use the accessory piping kit or the pipes

purchased locally.

- Measure the distance between the indoor

and the outdoor unit.

- Cut the pipes a little longer than measured

distance.

- Cut the cable 1.5m longer than the pipe length.

Burrs removal

- Completely remove all burrs from the cut

cross section of pipe/tube.

- Put the end of the copper tube/pipe to down-

ward direction as you remove burrs in order

to avoid to let burrs drop in the tubing.

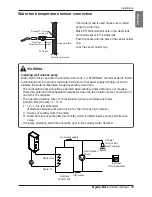

Pipe welding

- Insert and weld the pipe.

- Always make sure to flow Nitrogen at

0.2kgf/cm2 within the pipe when welding.

- If the welding is done without flowing Nitrogen,

it can generate a thick oxidized coating within

the pipe to interfere with normal operation of

valve and compressor etc.

Insulation

- Use rubber foamed insulation material

(EPDM, NBR) with high thermal resistance.

- When installed in humid environment, use

thicker insulation material than usual.

- Insert the insulation material within the prod-

uct as deep as possible.

h

The thickness of the above insulation material is

based on thermal conduction rate of 0.036W/m°C.

Copper

tube

90°

Slanted Uneven Rough

Pipe

Reamer

Point down

Copper tube

Direction of Nitrogen

Regulator

Taping

Valve

Nitrogen

Nitrogen

Nitrogen

Panel

Inside product

Insulation

Copper

tube

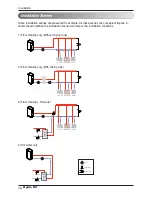

Refrigerant Piping

Classification

Thickness

Gas pipe(Ø15.88 – 4HP)

(Ø22.2 - 8HP)

t19 above

CAUTION

There is no pump-down function because

Hydro Kit

is the only heating unit. After vacuum drying,

recharge the refrigerant.

Содержание ARNH08GK3A2

Страница 49: ......