Page 46

TABLE 35

580682

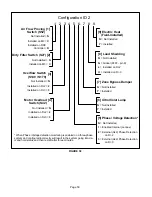

LGH/LCH092H4M, 102H4M, 120H4M, 150H4M (2-Compressor) Staged Belt Drive

Para

meter

Factory Setting

Field

Setting

Description

092

102

120

150

Note: Any changes to Smoke CFM setting must be adjusted before the other CFM settings. Use SETTINGS > RTU OPTIONS > EDIT

PARAMETERS

12

3000

CFM

3400

CFM

4000

CFM

5000

CFM

CFM

Blower CFM during smoke detection.

SETUP > TEST & BALANCE (can also use SETTINGS > RTU OPTIONS > BLOWER > SPEEDS)

3000

CFM

3400

CFM

4000

CFM

5000

CFM

CFM

Blower CFM during heating.

2700

CFM

2200

CFM

3600

CFM

4500

CFM

CFM

Blower CFM during high speed (2 compressor) cooling.

1950

CFM

3050

CFM

2600

CFM

3250

CFM

CFM

Blower CFM during low speed (1 compressor) cooling.

3000

CFM

3400

CFM

4000

CFM

5000

CFM

CFM

Blower CFM during ventilation.

*Once all four blower settings are entered, the target (highest of the heating and cooling settings) CFM will be displayed. Once the target CFM is

saved, all other blower CFM are set by the Unit Controller.

SETUP > TEST & BALANCE (can also use SETTINGS > RTU OPTIONS > DAMPER)

0%

0%

0%

0%

%

Damper min. position during LOW blower operation.

0%

0%

0%

0%

%

Damper min. position during HIGH blower operation.

50%

50%

50%

50%

%

Min. damper % for stage 1 power exhaust operation.

SETTINGS > RTU OPTIONS > EDIT PARAMETERS

29

101%

101%

101%

101%

%

Open

Damper minimum position during G blower operation. (Setting parameter 29 to “101”

disables parameter 29 and passes control to parameter 9 or 132)

216

5%

5%

5%

5%

%

Deadband % for stage 1 power exhaust operation.

TABLE 36

580686

LGH/LCH094U4M, 122U4M, 152U4M (2-Compressor) Staged Belt Drive

Paramet

er

Factory Setting

Field

Setting

Description

094

122

152

Note: Any changes to Smoke CFM setting must be adjusted before the other CFM settings. Use SETTINGS > RTU OPTIONS > EDIT

PARAMETERS

12

3000 CFM

4000 CFM

5000 CFM

CFM

Blower CFM during smoke detection.

SETUP > TEST & BALANCE (can also use SETTINGS > RTU OPTIONS > BLOWER > SPEEDS)

3000 CFM

4000 CFM

5000 CFM

CFM

Blower CFM during heating.

2700 CFM

3600 CFM

4500 CFM

CFM

Blower CFM during high speed (2 compressor) cooling.

1950 CFM

2600 CFM

3250 CFM

CFM

Blower CFM during low speed (1 compressor) cooling.

3000 CFM

4000 CFM

5000 CFM

CFM

Blower CFM during ventilation.

*Once all four blower settings are entered, the target (highest of the heating and cooling settings) CFM will be displayed. Once the target CFM is

saved, all other blower CFM are set by the Unit Controller.

SETUP > TEST & BALANCE (can also use SETTINGS > RTU OPTIONS > DAMPER)

0%

0%

0%

%

Damper min. position during LOW blower operation.

0%

0%

0%

%

Damper min. position during HIGH blower operation.

50%

50%

50%

%

Min. damper % for stage 1 power exhaust operation.

SETTINGS > RTU OPTIONS > EDIT PARAMETERS

29

101%

101%

101%

%

Open

Damper minimum position during G blower operation. (Setting paramet

er 29 to “101” disables parameter 29 and passes control to parameter 9

or 132)

216

5%

5%

5%

%

Deadband % for stage 1 power exhaust operation.

SETTINGS > RTU OPTIONS > EDIT PARAMETER

85

40°F

40°F

40°F

°F

Compressor 1 low temp lockout. Settings lower than 40°F could void

warranty.

86

40°F

40°F

40°F

°F

Compressor 2 low temp lockout. Settings lower than 40°F could void

warranty.