Page 16

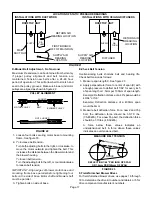

DIRECT DRIVE BLOWER ASSEMBLY

FIGURE 20

INLET

GRID

REMOVE TWO SCREWS

ON EACH SIDE TO SLIDE

BLOWER OUT OF UNIT

BLOWER

HOUSING

BLOWER MOTOR

SECURED TO THIS

SIDE OF HOUSING

C-Determining Unit CFM

Belt Drive Blowers Controlled By An Inverter

IMPORTANT - Belt-driven inverter units are factory-set to

run the blower at full speed (60Hz) when there is a blower

(G) demand without a heating or cooling demand. Refer

to the field-provided, design specified CFM for all modes

of operation. Use the following procedure to adjust motor

pulley to deliver the highest CFM called for in the design

spec. See Inverter Start-Up section to set blower speeds

for all modes once the motor pulley is set.

IMPORTANT - Direct drive variable blower unit CFM is

determined by the Unit Controller. Refer to the Direct

Drive Variable Speed Start-Up section.

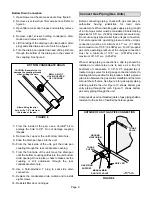

1- The following measurements must be made with a

dry indoor coil. Run blower (G demand) without a

cooling demand. Measure the indoor blower shaft

RPM. Air filters must be in place when measurements

are taken.

2- With all access panels in place, measure static

pressure external to unit (from supply to return).

Blower performance data is based on static pressure

readings taken in locations shown in figure 21.

Note - Static pressure readings can vary if not taken

where shown.

3- Referring to pages 19 through 22, use static pressure

and RPM readings to determine unit CFM. Apply

accessory air resistance tables when installing units

with any of the optional accessories listed.

NOTE - The minimum air volume required for use with

optional electric heat (maximum static pressure - 2.0

in.w.g) is 2800 CFM for 7.5Kw, 15Kw, 22.5Kw, 30Kw and

45Kw and 4000 CFM for 60Kw.

4-

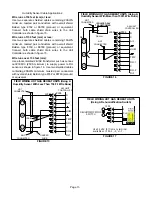

Blowers Without Belt Tensioner-

The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley

clockwise to increase CFM. Turn counterclockwise to

decrease CFM. See figure 18. Do not exceed

minimum and maximum number of pulley turns as

shown in table 3.

Blowers Equipped With Belt Tensioner-

Refer to label on motor base. See figure 19.

TABLE 3

MINIMUM AND MAXIMUM PULLEY ADJUSTMENT

Belt

Minimum

Turns Open

Maximum

Turns Open

A Section

0

5

B Section

1*

6

*No minimum turns open when B belt is used on pulleys 6” O.D. or larger.