Page 16

LGH/LCH420, 480, 540, 600

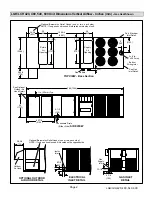

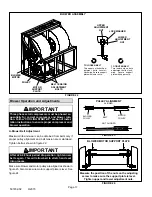

FIGURE 21

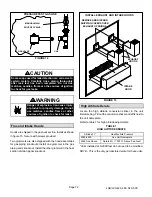

FIELD WIRING HOT GAS REHEAT UNITS

(Using A Humidity Sensor With More

Than 150 Ft. Wire Runs)

ISOLATED 24V

TRANSFORMER

9

8

P298

J298A

1

2

B

3

4

C

5

6

7

D

10

A91

VIN

VO

GND

R

C

AI-1

HUM

TMP

DO-1

C

DI-1

DO-2

NOT

CONNECTED

NOT

CONNECTED

DRAIN

A55 UNIT

CONTROLLER

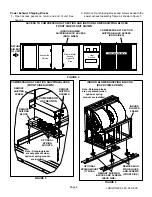

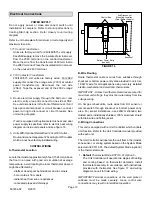

VFD Supply Air Blower Start-Up

This section is used when the unit is equipped with an

optional variable frequency drive (VFD) supply air blower.

Install static pressure transducer before start-up; see

Optional Supply Air VFD section in this manual.

A-Set Static Pressure Setpoints

Refer to the Unit Controller manual provided with the unit.

1- Open all zone dampers and/or boxes.

2- Locate the Unit Controller in the control box. Refer to

the dimension illustration in the front of this manual.

Refer to the Unit Controller Installation and Setup Guide to

change the System Mode. Use the menu navigation arrows

and select button; see

Settings - Install

.

3- Apply power and use the Unit Controller to start the

blower. Press the menu navigation arrows and select

button to initiate the blower. Refer to the

Service - Test

menu in the Unit Controller manual. Allow blower

speed to stabilize.

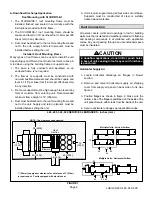

4- Locate TB18 under Unit Controller. Read the DC

voltage at terminals 6 (+) and 10 (-). Divide reading by

2 to determine system static pressure.

TB18-6 & 10

Voltage

__

.

.

2

= System Static “w.c.

5- Static pressure setpoints are factory-set at 1”w.c.

Change the setpoints to match the static calculated in

the previous step or to design specifications. Refer to

the

Setting - Control - ECTO

menu in the Unit Controller

manual. In addition, reference tables 2 and 3. Record

new setpoints in table 4.

6- The Unit Controller is factory-set to shut the unit off if

duct pressure exceeds 2.0”w.c. longer than 20

seconds. This pressure can be changed using ECTO

parameter 0.21. Refer to the Unit Controller manual.

TABLE 2

VFD SUPPLY AIR STATIC PRESSURE SETPOINTS

ECTO

Changes Static Pressure Setpoint

0.02

Unit de-energized during smoke detection. See ECTO

5.01 to operate blower during smoke detection.

0.03

During ventilation

0.04

During heating

0.05

During cooling

TABLE 3

VFD SUPPLY AIR STATIC PRESSURE SETPOINTS

Pressure ”w.c.

DC Voltage

Display Setting

0.00

0.00

0

0.25

0.50

13

0.50

1.00

25

0.75

1.50

38

1.00

2.00

51

1.25

2.50

64

1.50

3.00

77

1.75

3.50

89

2.00

4.00

102

2.25

4.50

115

2.50

5.00

128

2.75

5.50

140

3.00

6.00

153

3.25

6.50

166

3.50

7.00

179

3.75

7.50

191

4.00

8.00

204

4.25

8.50

217

4.50

9.00

230

4.75

9.50

242

5.00

10.00

255

TABLE 4

RECORD ADJUSTED SETPOINTS

ECTO

Setpoint

Description

Setpoint

“w.c.

Display

Setting

0.02

Smoke

0.03

Ventilation

0.04

Heating

0.05

Cooling

B-Unit Operation

Use the Unit Controller to check unit mechanical operation.

See the

Service - Test

section of the Unit Controller manual.