5. Inspect spark plugs for cracked porcelain, pitted

electrodes, or other wear and damage. Replace the

spark plug if necessary.

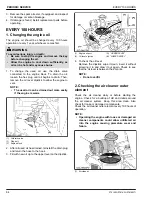

(1) Spark plug cap and spark plug

NOTE :

• Do not clean the spark plug in a machine

using abrasive grit. Some grit could remain

in the spark plug and enter the engine,

which may cause extensive wear and

damage.

Recommended spark plug

NGK BPR4ES

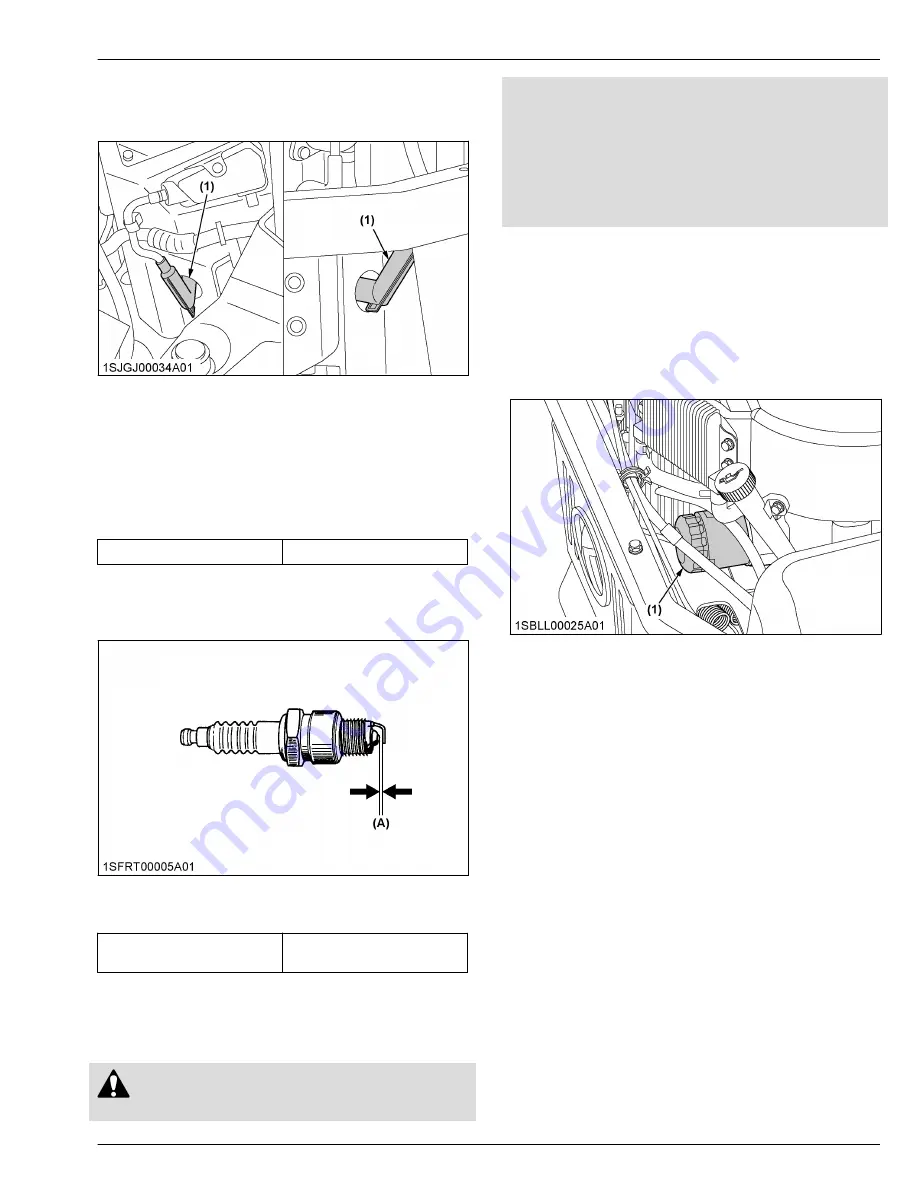

6. Check the gap using a wire feeler gauge. Adjust the

gap to 0.76 mm (0.030 in.) by carefully bending the

ground electrode.

(A) 0.76 mm (0.030 in.)

7. Reinstall the spark plug into the cylinder head.

Tightening torque

22 N

⋅

m

16 lbf

⋅

ft

EVERY 200 HOURS

1. Replacing the engine oil filter

WARNING

To avoid serious injury or death:

• Engine oil is a toxic substance. Dispose of used

oil properly. Contact your local authorities for

approved disposal methods or possible

recycling.

• Be sure to stop the engine and remove the key

before changing the oil and the oil filter.

• Allow engine to cool down sufficiently; oil can

be hot and may cause burns.

The oil filter must be changed every 200 service hours.

Always use a genuine oil filter.

1. Drain the engine oil.

Drain the engine oil by following steps 1 and 2 from

changing engine oil section.

(See Changing the engine oil on page 64.)

2. Remove the old filter and wipe off the filter adapter

with a clean cloth.

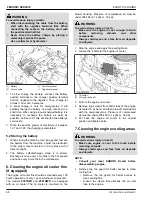

(1) Engine oil filter

3. Place a new replacement filter in a shallow pan with

the open end up. Pour new oil, of the proper type, in

the threaded center hole. Stop pouring when the oil

reaches the bottom of the threads. Allow a few

minutes for the oil to be absorbed by the filter

material.

4. Apply a thin film of clean oil to the rubber gasket on

the new oil filter.

5. Install the new oil filter to the filter adapter. Hand

tighten the filter clockwise until the rubber gasket

contacts the adapter, then tighten the filter an

additional 2/3 turn.

6. Fill the engine with the proper oil up to the

[FULL]

or

[F]

mark on the dipstick. Always check the oil

level with the dipstick before adding more oil.

7. Reinstall the oil fill cap and dipstick, and then

tighten securely.

EVERY 200 HOURS

PERIODIC SERVICE

Z751KWi,Z781KWi,Z781KWTi

71

Содержание Z751KWi

Страница 3: ...OPERATOR S MANUAL 1SJGJ00001A01 READ AND SAVE THIS MANUAL MODELS Z751KWi Z781KWi Z781KWTi ...

Страница 15: ...SAFETY LABELS SAFE OPERATION 10 Z751KWi Z781KWi Z781KWTi ...

Страница 16: ...SAFE OPERATION Z751KWi Z781KWi Z781KWTi 11 ...

Страница 17: ...SAFE OPERATION 12 Z751KWi Z781KWi Z781KWTi ...

Страница 18: ...SAFE OPERATION Z751KWi Z781KWi Z781KWTi 13 ...

Страница 19: ...SAFE OPERATION 14 Z751KWi Z781KWi Z781KWTi ...

Страница 21: ...16 Z751KWi Z781KWi Z781KWTi ...

Страница 59: ...PERIODIC SERVICE CHART LABEL MAINTENANCE PERIODIC SERVICE CHART LABEL 54 Z751KWi Z781KWi Z781KWTi ...