ROTEX

®

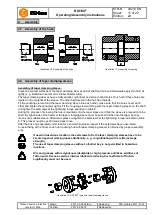

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

3 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

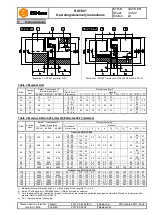

Illustration 1: ROTEX

®

(material: Al-D)

Illustration 2: ROTEX

®

(material: EN-GJL-250/EN-GJS-400-15)

Table 1: Material Al-D

Size

Compo

nent

Spider

1)

(component 2)

Rated torque [Nm]

Dimensions [mm]

3)

Finish bore

2)

d (min-max)

General

92 ShA

98 ShA

64 ShD

L

l

1

; l

2

E

b

s

D

H

D

Z

D

Z1

4)

d

H

D;D

1

N

14

1a

7.5

12.5

-

6 - 16

35

11

13

10

1.5

30

-

-

10

30

-

19

1

10

17

-

6 - 19

66

25

16

12

2.0

41

-

-

18

32

20

1a

19 - 24

41

24

1

35

60

-

9 - 24

78

30

18

14

2.0

56

-

-

27

40

24

1a

22 - 28

56

28

1

95

160

-

10 - 28

90

35

20

15

2.5

67

-

-

30

48

28

1a

28 - 38

67

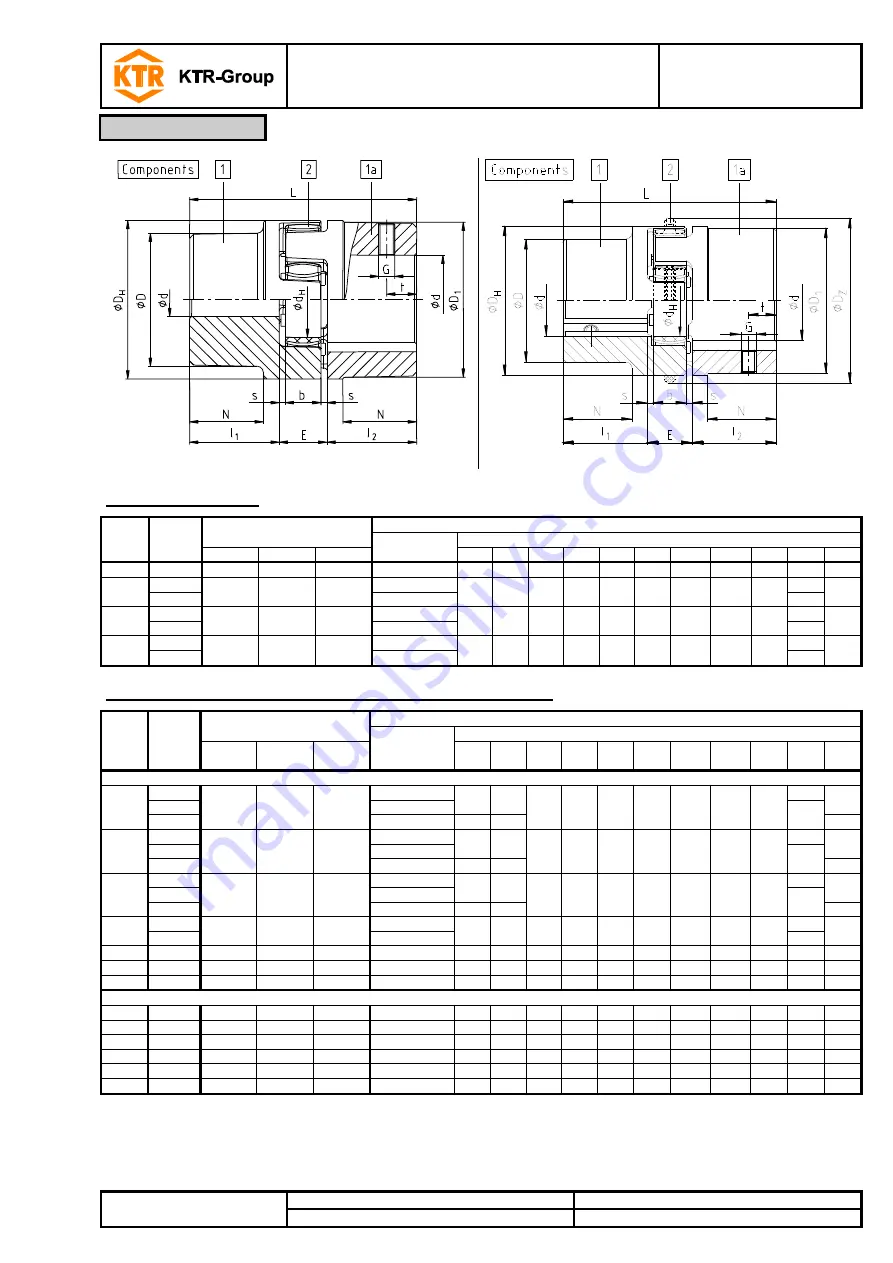

Table 2: Material EN-GJL-250 (GG 25)/EN-GJS-400-15 (GGG 40)

Size

Compo

nent

Spider

1)

(component 2)

Rated torque [Nm]

Dimensions [mm]

3)

Finish bore

2)

d (min-max)

General

92 ShA

98 ShA

64 ShD

L

l

1

; l

2

E

b

s

D

H

D

Z

D

Z1

4)

d

H

D;D

1

N

Cast iron EN-GJL-250

38

1

190

325

405

12 - 40

114

45

24

18

3.0

80

-

-

38

66

37

1a

38 - 48

78

1b

12 - 48

164

70

62

42

1

265

450

560

14 - 45

126

50

26

20

3.0

95

-

-

46

75

40

1a

42 - 55

94

1b

14 - 55

176

75

65

48

1

310

525

655

15 - 52

140

56

28

21

3.5

105

-

-

51

85

45

1a

48 - 62

104

1b

15 - 62

188

80

69

55

1

410

685

825

20 - 60

160

65

30

22

4.0

120

-

-

60

98

52

1a

55 - 74

118

65

1

625

940

1175

22 - 70

185

75

35

26

4.5

135

-

-

68

115

61

75

1

1280

1920

2400

30 - 80

210

85

40

30

5.0

160

-

-

80

135

69

90

1

2400

3600

4500

40 - 97

245

100

45

34

5.5

200

218

230

100

160

81

Nodular iron EN-GJS-400-15

100

1

3300

4950

6185

50 - 115

270

110

50

38

6.0

225

246

260

113

180

89

110

1

4800

7200

9000

60 - 125

295

120

55

42

6.5

255

276

290

127

200

96

125

1

6650

10000

12500

60 - 145

340

140

60

46

7.0

290

315

330

147

230

112

140

1

8550

12800

16000

60 - 160

375

155

65

50

7.5

320

345

360

165

255

124

160

1

12800

19200

24000

80 - 185

425

175

75

57

9.0

370

400

415

190

290

140

180

1

18650

28000

35000

85 - 200

475

185

85

64

10.5

420

450

465

220

325

156

1) Maximum torque of the coupling T

Kmax.

= rated torque of the coupling T

K rated

x 2

2) Bores H7 with keyway to DIN 6885 sheet 1 [JS9] and thread for setscrew

3) For dimensions G and t see table 6; threads for setscrews are located opposite the keyway with material Al-D and on the keyway with

material EN-GJL-250/EN-GJS-400-15

4) D

Z1

= internal diameter of housing

1

Technical data