ROTEX

®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

19 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

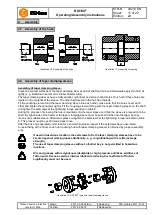

2. Mining

Equipment group I of category M2 (coupling is not approved for equipment group M1).

Permissible ambient temperature - 30 °C to + 90 °C (valid for T-PUR

®

only: - 50 °C to + 120 °C).

Explosion group

Inspection intervals

3G

3D

For couplings which are classified in category 3G or 3D the operating and assembly

instructions that are usual for standard operation apply. During the standard operation

which has to be subject to the ignition risk analysis the couplings are free from any ignition

source. Merely the temperature increase produced by self-heating and depending on the

coupling type has to be considered:

for ROTEX

®

:

T = 20 K

II 2GD c IIB

T4, T5, T6

An inspection of the torsional backlash and a visual inspection of the flexible spider/DZ

elements must be performed after 3,000 operating hours for the first time, at the latest after

6 months after start-up of the coupling.

If you note insignificant or no wear on the spider/DZ elements upon this initial inspection,

further inspections can each be performed after 6,000 operating hours or at the latest after

18 months, provided that the operating parameters remain the same.

If you note significant wear during the initial inspection so that it would be recommendable

to replace the spider/DZ elements, please find out the cause according to the table

„Breakdowns“, if possible.

The maintenance intervals must be adjusted to the modified operating parameters without

fail.

II 2GD c IIC

T4, T5, T6

An inspection of the torsional backlash and a visual inspection of the flexible spider/DZ

elements must be performed after 2,000 operating hours for the first time, at the latest after

3 months after start-up of the coupling.

If you note insignificant or no wear on the spider/DZ elements upon this initial inspection,

further inspections can each be performed after 4,000 operating hours or at the latest after

12 months, provided that the operating parameters remain the same.

If you note significant wear during the initial inspection so that it would be recommendable

to replace the spider/DZ elements, please find out the cause according to the table

„Breakdowns“, if possible.

The maintenance intervals must be adjusted to the modified operating parameters without

fail.

Hubs, clamping hubs or similar types without feather keyways may be used in category 3

only.

10

Enclosure A

Advice and instructions regarding the use in

hazardous locations

10.1 Intended use in

hazardous locations

10.2 Inspection intervals for couplings in

hazardous locations