ROTEX

®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

4 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

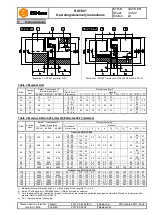

Illustration 3: ROTEX

®

(material: steel)

Illustration 4: ROTEX

®

, type DKM

5)

Table 3: Material steel

Size

Compo

nent

Spider

1)

(component 2)

Rated torque [Nm]

Dimensions [mm]

3)

Finish bore

2)

d (min-max)

General

92 ShA

98 ShA

64 ShD

L

l

1

; l

2

E

b

s

D

H

D

Z

D

Z1

4)

d

H

D

N

14

1a

7.5

12.5

16

0 - 16

35

11

13

10

1.5

30

-

-

10

30

-

1b

50

18.5

19

1a

10

17

21

0 - 25

66

25

16

12

2.0

40

-

-

18

40

-

1b

90

37

24

1a

35

60

75

0 - 35

78

30

18

14

2.0

55

-

-

27

55

-

1b

118

50

28

1a

95

160

200

0 - 40

90

35

20

15

2.5

65

-

-

30

65

-

1b

140

60

38

1

190

325

405

0 - 48

114

45

24

18

3.0

80

-

-

38

70

27

1b

164

70

80

-

42

1

265

450

560

0 - 55

126

50

26

20

3.0

95

-

-

46

85

28

1b

176

75

95

-

48

1

310

525

655

0 - 62

140

56

28

21

3.5

105

-

-

51

95

32

1b

188

80

105

-

55

1

410

685

825

0 - 75

160

65

30

22

4.0

120

-

-

60

110

37

1b

210

90

120

-

65

1

625

940

1175

0 - 80

185

75

35

26

4.5

135

-

-

68

115

47

1b

235

100

135

-

75

1

1280

1920

2400

0 - 95

210

85

40

30

5.0

160

-

-

80

135

53

1b

260

110

160

-

90

1

2400

3600

4500

0 - 110

245

100

45

34

5.5

200

218

230

100

160

62

1b

295

125

200

-

Table 4: Type DKM

5)

Size

Spider

1)

(component 2)

Rated torque [Nm]

Dimensions [mm]

3)

Dimensions

d, D, D

1

General

92 ShA

98 ShA

L

DKM

l

1

; l

2

E

b

s

D

H

d

H

l

11

l

12

19

10

17

s

e

e

t

a

b

le

1

t

o

3

92

25

16

12

2.0

40

18

10

42

24

35

60

112

30

18

14

2.0

55

27

16

52

28

95

160

128

35

20

15

2.5

65

30

18

58

38

190

325

158

45

24

18

3.0

80

38

20

68

42

265

450

174

50

26

20

3.0

95

46

22

74

48

310

525

192

56

28

21

3.5

105

51

24

80

55

410

685

218

65

30

22

4.0

120

60

28

88

65

625

940

252

75

35

26

4.5

135

68

32

102

75

1280

1920

286

85

40

30

5.0

160

80

36

116

90

2400

3600

330

100

45

34

5.5

200

100

40

130

1) Maximum torque of the coupling T

Kmax.

= rated torque of the coupling T

K rated

x 2

2) Bores H7 with keyway to DIN 6885 sheet 1 [JS9] and thread for setscrew

3) For dimensions G and t see table 6; threads for setscrews are located opposite the keyway with material Al-D and on the keyway with

material EN-GJL-250/EN-GJS-400-15

4) D

Z1

= internal diameter of housing

5) Type DKM not available with DZ elements.

1

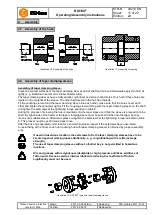

Technical data