ROTEX

®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

16 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

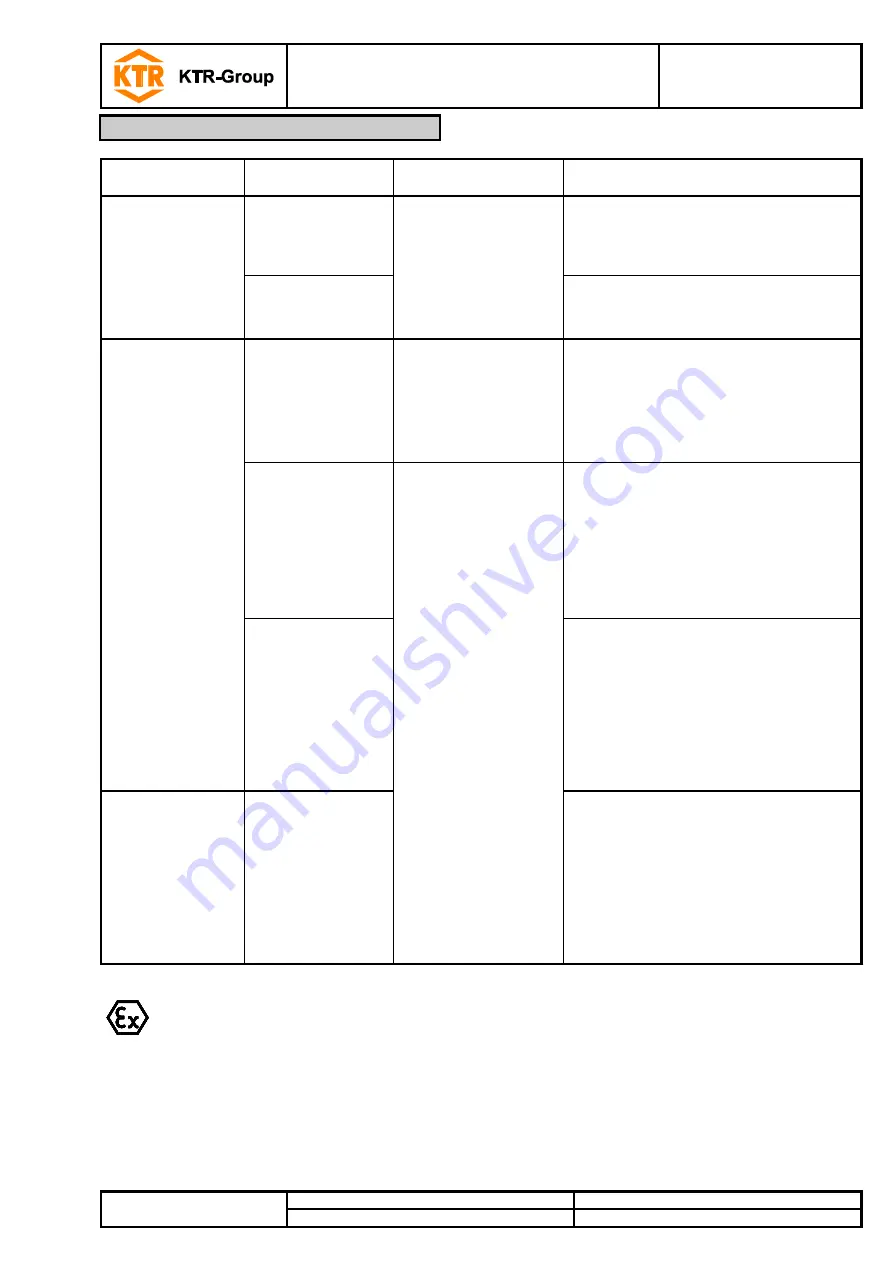

Breakdowns

Causes

Hazard notes for

hazardous locations

Elimination

Breaking of cams

Operating parameters

do not meet with the

performance of the

coupling

Ignition risk due to

sparking

1) Set the unit out of operation

2) Review the operating parameters and select

a bigger coupling (consider mounting space)

3) Assemble new coupling size

4) Inspect alignment

Operating error of the

unit

1) Set the unit out of operation

2) Replace complete coupling

3) Inspect alignment

4) Instruct and train the service staff

Early wear of spider

Misalignment

Increased temperature on

the spider surface; ignition

risk by hot surfaces

1) Set the unit out of operation

2) Eliminate the reason for the misalignment

(e. g. loose foundation bolts, breaking of the

engine mount, heat expansion of unit

components, modification of the installation

dimension E of the coupling)

3) For inspection of wear see item inspection

e. g. contact with

aggressive liquids/oils,

ozone influence, too

high/low ambient

temperatures etc.

causing physical

modification of the

spider

Ignition risk due to

sparking with metallic

contact of the cams

1) Set the unit out of operation

2) Disassemble the coupling and remove

remainders of the spider

3) Inspect coupling components and replace

coupling components that are damaged

4) Insert spider, assemble coupling

components

5) Inspect alignment, adjust if necessary

6) Make sure that further physical

modifications of the spider are excluded

Ambient/contact

temperatures which

are too high for the

spider, max.

permissible

e. g. with T-PUR

®

T4 = - 50 °C/

+ 120 °C

1) Set the unit out of operation

2) Disassemble the coupling and remove

remainders of the spider

3) Inspect coupling components and replace

coupling components that are damaged

4) Insert spider, assemble coupling

components

5) Inspect alignment, adjust if necessary

6) Inspect and adjust ambient/contact

temperature (possibly corrective by using

different spider materials)

Early wear of spider

(liquefaction of

material inside the

spider cam)

Vibrations of drive

1) Set the unit out of operation

2) Disassemble the coupling and remove

remainders of the spider

3) Inspect coupling components and replace

coupling components that are damaged

4) Insert spider, assemble coupling

components

5) Inspect alignment, adjust if necessary

6) Find out the reason for the vibrations

(possibly corrective by spider with lower or

higher Shore hardness)

If you operate with a worn spider/DZ elements (see item 10.3) and with the subsequent

contact of metal parts a proper operation meeting the explosion protection requirements

and acc. to directive 2014/34/EU is not ensured.

6

Breakdowns, causes and elimination