ROTEX

®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

11 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

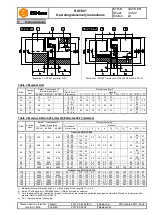

Illustration 10: Assembly of the hubs

Illustration 11: Assembly of coupling

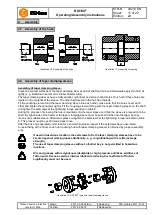

Assembly of taper clamping sleeve:

Clean the contact surfaces of the taper clamping sleeves and of shaft and hub and afterwards apply thin fluid oil

lightly (e. g. Ballistol Universal oil or Klüber Quietsch-Ex).

The taper clamping sleeves have axially parallel, cylindrical and smooth blind holes. Only half of these holes are

located in the material of the sleeve. The other half located in the hub has threads.

Fit the coupling element and the taper clamping sleeve into each other, make sure that the bores cover each

other and tighten the setscrews lightly. Fit the coupling element along with the taper clamping sleeve on the shaft

and tighten the setscrews at the tightening torque specified in table 8.

During the process of screwing the hub is mounted onto the taper sleeve and thus the sleeve is pressed onto the

shaft. By light blows of the hammer the taper clamping sleeve must be pushed further into the taper bore by

means of a suitable sleeve. Afterwards please re-tighten the setscrews at the tightening torque indicated in table

8. This process must be performed at least once.

After the drive has operated under load for a short while please inspect if the setscrews have unscrewed.

An axial fixing of the Taper Lock hub (coupling hub with taper clamping sleeve) is obtained by proper assembly

only.

!

If used in hazardous locations the setscrews to fix the taper clamping sleeves have to be

secured against working loose additionally, e. g. conglutinating with Loctite (average

strength).

The use of taper clamping sleeves without a feather key is not permitted in hazardous

locations.

!

Oils and greases with molybdenum disulphide or high-pressure additives, additives of

Teflon and silicone as well as internal lubricants reducing the coefficient of friction

significantly must not be used.

Illustration 12: ROTEX

®

, type with taper clamping sleeve

4

Assembly

4.3 Assembly of the hubs

4.4 Assembly of taper clamping sleeve