IK-12 NEXT

-

2

-

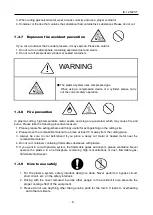

1.1.2 Safety clothing

1. Be sure to wear protectors gauntlets, goggles, helmet, and safety shoes during operation.

2. Avoid operating the machine with wet clothes or hands in order to prevent electric shock.

1.1.3 Operation and handling safety precautions

1. Read this instruction manual before operating the machine.

2. Mount and center the machine correctly and confirm correct motion before operation.

3. Before connecting the power plug to the outlet, make sure that the power switch is in the OFF

position (or the normal / reverse changeover switch is in the stop position.

4. Prior to operating the machine, check the safety of the surroundings to avoid accidents.

5. Never move the machine while the preheat flame is on.

6. Take great care of spatters and dross when operating the machine at a high position. They may

injure people below.

7. Make sure that the clutch is engaged before letting the machine travel. Improper clutch

engagement will cause machine failure.

8. Be careful not to get you hand caught between rails when connecting them.

9. When cutting on the rail, correctly fix the caster.

10. Correctly fix the heat prevention plate so that it will not touch the rail.

11. To prevent the torch holder from dropping, fix it with the wing bolt (BS-6x22) on the torch slide.

12. Be sure to hold the handle when carrying the machine.

13. Be sure to remove the machine from the rail when moving the rail.

1.1.4 Electrical system precautions

1. Be sure to check the input power voltage of the machine before operation. The input power voltage

should be in the range of

±

10% of the rated voltage. The machine should not be operated out of this

range.

2. The metal plugs are screw-threaded, therefore, fully tighten them so that they will not come loose

during operation.

3. The ground pin is attached to the rubber plug of a cabtyre cord. Please use a power receptacle with a

ground pin opening.

4. Stop operation and turn off the power in the following cases,

and ask a qualified electrician to repair the machine.

1) Broken or abraded cables

2) Water leakage from the machine or liquid damage to the machine

3) Abnormal machine operation despite operating the machine according to the instruction manual

4) Machine breakdown

5) Poor machine performance that requires repair

5. Periodically inspect the electrical system.

1.1.5 Maintenance and inspection precautions

1. Ask a qualified electrician to perform repair and inspection service.

2. Disconnect the power plug before inspecting and repairing the machine.

3. Maintain the machine periodically.

Содержание IK-12 NEXT

Страница 50: ...IK 12 NEXT 46 10 Wiring diagram...

Страница 51: ...IK 12 NEXT 47 11 Assembly drawing of IK 12 NEXT 215mm 8 465inch 220mm 8 661inch 432mm 17 008inch...

Страница 52: ...IK 12 NEXT 48 012 Parts list 12 1 Main body and inside parts...

Страница 54: ...IK 12 NEXT 50 12 2 Outside parts...

Страница 56: ...IK 12 NEXT 52 12 3 Electrical parts 103...