JL-M MATERIAL SAFETY DATA SHEET

Page 1 of 1

SECTION 1 – PRODUCT IDENTIFICATION

Product Name: JL-M Lubricant

Revised:

03/07/03 Supercedes: 03/17/00

Prepared by: C. Semerod

Emergency Information: (412) 279-1149

Manufacturer’s Name: Superbolt, Inc.

Manufacturer’s Address: 1000 Gregg Street

Carnegie, PA 15106

Manufacturer’s Phone #: (412) 279-1149

SECTION 2 – HAZARDOUS INGREDIENTS

CHEMICAL NAME:

CAS

NO.: OSHA

PEL: ACGIH TLV: (STEL)

Molybdenum Disulfide

1317-33-5

10 mg/m3

10 mg/m3 N/A

Silica, Fused

60676-86-0

0.1 mg/m3 0.1 mg/m3 N/A

Graphite 7782-42-5 2 mg/m3 N/A

Silica, Crystalline 14808-60-7 0.1 mg/m3 N/A

Lubricating Oils, Petroleum,

64742-58-1

5 mg/m3*

5 mg/m3*

10mg/m3*

Hydrotreated, Spent

Residual Oils (Petroleum),

64742-62-7

5 mg/m3*

5 mg/m3*

10 mg/m3*

Solvent Dewaxed

Solvent-Refined Heavy Paraffinic

64741-88-4

5 mg/m3*

5 mg/m3*

10 mg/m3*

Distillate (Petroleum)

Solvent –Dewaxed Hydrotreated

64742-65-0

5 mg/m3*

5 mg/m3*

10 mg/m3*

Heavy Paraffinic Distillate (Petroleum)

Hydrotreated Heavy Paraffinic

64742-54-7

5 mg/m3*

5 mg/m3*

10 mg/m3*

Distillate (Petroleum)

Proprietary Additives Mixture (<1%)

(*)

Designates limits set by OSHA and the ACGIH for oil mist. This product is sold in a paste form so misting should not occur.

SECTION 3 – PHYSICAL DATA

SECTION 4 – FIRE AND EXPLOSION DATA

Appearance and Odor: Dark Grey Paste, Mild Petroleum

Boiling Point: > 500 degrees F

% Volatile: 0%

Vapor Density: > 1 (Air = 1)

Evaporation Rate: < 1 (Ether = 1)

Specific Gravity: 4.8 (Water = 1)

Vapor Pressure: Essentially 0 (mm Hg)

Solubility in Water: Insoluble

pH: N/A

Flash Point: 338 degrees F

Lower Explosive Limit: N/A

Upper Explosive Limit: N/A

Extinguishing Media: Carbon Dioxide, Regular Foam, Dry Chemical

Special Fire Fighting Procedures: Fire may produce dense smoke,

firefighters should wear self contained breathing apparatus. Use

water to cool fire exposed containers.

Unusual Fire & Explosion Hazards: Decomposition and combustion

by-products may be toxic. Heated containers may rupture or explode.

SECTION 5 – REACTIVITY DATA

SECTION 6 – STORAGE & HANDLING

Stability: Stable Hazardous Polymerization: Will not occur.

Incompatibility: Avoid contact with oxidizing agents, heat, sparks or

flame.

Hazardous Combustion By-Products: Carbon Monoxide, Sulfur

Dioxide, Aldehydes, and Nitrogen Oxides

Hazardous Decomposition: Thermal decomposition may yield

methacrylate monomers.

Handling Precautions: Use good personal hygiene practices. Clean

contaminated clothing and protective equipment before reuse.

Storage Precautions: Store in a cool dry location. Keep container

tightly closed when not in use and during transport. Keep away from

open sparks or flames.

SECTION 7 – HEALTH HAZARDS

Effects of Overexposure:

Skin: May Cause Irritation

Eyes: Eye Irritant. May cause redness and Blurred vision.

Ingestion: Not Expected

Inhalation: Not Expected (Chronic respiratory diseases may be

aggravated by dust exposure.)

NFPA CODES: Health: 1

Flammability: 1

Reactivity: 0

Carcinogenicity: Silica is a suspected carcinogen in a respirable

form by the IARC and NTP however, not by the ACIGH or OSHA.

First Aid Procedures:

Skin: Remove contaminated clothing from irritated area. Flush

exposed area with mild soap and water. Seek medical attention if

irritation persists.

Eyes: Flush eyes with large quantities of water, holding eyelids open.

Seek medical attention if irritation persists.

Ingestion: Do not induce vomiting. If spontaneous vomiting occurs,

keep head below hips to avoid aspiration into the lungs. Seek

immediate medical attention.

Inhalation: Remove to fresh air. Obtain medical attention if

necessary.

SECTION 8 – SPECIAL PROTECTION

SECTION 9 – SPILL AND DISPOSAL PROCEDURES

Eye Protection: Safety Glasses or Face Shield

Protective Gloves: Recommended

Respiratory Protection: Avoid breathing dust, use an

approved respirator if levels exceed OSHA limits.

Ventilation: Local ventilation to maintain levels within OSHA limits.

Spill Procedures: Scrape or wipe up any spilled material. Wear

proper protective equipment when cleaning up a spill.

Disposal Procedures: Dispose of in accordance with any applicable

federal, state, or local laws.

The information in this MSDS was obtained from sources which we believe are reliable. However, the information is provided without any

representation or warranty, expressed or implied, regarding the accuracy or correctness. The conditions or methods of handling, storage, use

and disposal of the product are beyond our control. For this and other reasons, we do not assume responsibility and expressly disclaim liability

for loss, damage, or expense arising out of or in any way connected with the handling, storage, use or disposal of the product.

KMT 20416125

Содержание STREAMLINE SL-V SRP 100

Страница 1: ...MANUAL 20428408 R08 STREAMLINE SL V SRP 100 WATERJET INTENSIFIER OPERATION AND MAINTENANCE MANUAL ...

Страница 23: ......

Страница 25: ......

Страница 174: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 5 Figure 12 1 SL V SRP 100 Intensifier Unit ...

Страница 176: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 7 Figure 12 2 Intensifier Assembly ...

Страница 180: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 11 Figure 12 5 Pneumatic Valve Actuator Assembly Normally Open ...

Страница 182: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 13 Figure 12 6 Hydraulic Piston Assembly 05136684 ...

Страница 184: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 15 Figure 12 7 High Pressure Piping ...

Страница 186: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 17 Figure 12 8 Low Pressure Water Filter Assembly ...

Страница 188: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 19 Figure 12 9 Hydraulic Power Package ...

Страница 190: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 21 Figure 12 10 Motor Pump Assembly ...

Страница 192: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 23 Figure 12 11 Hydraulic Manifold Assembly ...

Страница 194: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 25 Figure 12 12 Hydraulic Hose Connections ...

Страница 196: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 27 Figure 12 13 Reservoir Assembly ...

Страница 199: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 30 Figure 12 14 Bulkhead Pipe Assembly ...

Страница 201: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 32 Figure 12 15 Cover Assembly ...

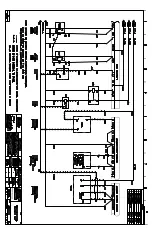

Страница 203: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 34 Figure 12 16 Electrical Assembly 200 208 50 60 ...

Страница 205: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 36 Figure 12 17 Electrical Assembly 230 50 60 ...

Страница 207: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 38 Figure 12 18 Electrical Assembly 380 415 50 60 ...

Страница 210: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 41 Figure 12 19 Controls Subassembly 200 208 230 50 60 ...

Страница 213: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 44 Figure 12 20 Controls Subassembly 380 415 50 60 ...

Страница 215: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 46 Figure 12 21 Control Panel Configuration 200 208 50 60 ...

Страница 217: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 48 Figure 12 22 Control Panel Configuration 230 50 60 ...

Страница 219: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 50 Figure 12 23 Control Panel Configuration 380 415 50 60 ...

Страница 221: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 52 Figure 12 24 Proportional Pressure Control 80075732 ...

Страница 223: ...Section 12 Parts List 20428786 2 2008 Rev 05 12 54 Figure 12 25 High Pressure Transducer ...

Страница 224: ......

Страница 225: ......

Страница 226: ......

Страница 227: ......

Страница 228: ......

Страница 229: ......

Страница 230: ......

Страница 231: ......

Страница 232: ......

Страница 233: ......

Страница 234: ......

Страница 235: ......

Страница 236: ......

Страница 237: ......

Страница 238: ......

Страница 239: ......