147

134

16

137

135

123

133

116

113

113, 116

135

135

134

134

132

134

134

134

134

Needle

thread

clamp

failure

Bobbin

thread at

the start

of sewing

is drawn

up on the

cloth.

Knife to cut

needle

thread is

dull.

Interference

of wiper

with needle

Phenomenon

Bird’s nest prevention (cB) type

1

Improper wiper position.

2

Air pressure drop.

3

Dust bag becomes excessively filled with

waste thread.

4

Thread trimmer or wiper operates when

needle does not enter the cloth.

5

Needle thread length is too short.

Thread does not reach the clamp head.

6

Uneven length of left and right needle threads

(Thread which is not stretched such as

cotton thread or the like is used.)

Adjust the wiper to the proper position.

Set the air pressure to 0.6Mpa.

Remove waste thread from the dust bag.

Operate thread trimmer or wiper on the

cloth.

Perform pre-tension adjustment and lengthen

needle thread. (Adjust the length from the

clamp head to approximately 20 to 35 mm.)

See page

Cause

Corrective measure

Step 1 :

Increase the drawing amount of needle

thread and increase needle thread

remaining amount at the start of sewing.

Step 2 :

Make tension release SOL (solenoid) actuate at

the start of sewing to perform tension release

and increase the thread remaining amount. (Input

the number of stitches of thread release at the

start of sewing with function setting No.100.)

Step 3 :

Make the thread drawing device actuate

again after completion of needle thread

clamp to perform tension release and

increase the thread remaining amount.

(Set function setting No.18 to 2.)

Step 4 :

Make all step items (1 + 2 + 3) function.

Replace the knife with a new one.

Adjust the position to the proper one.

Change the thread count.

Change to the normal feed.

Adjust the UP stop position.

Re-adjust the locus of the wiper.

Re-adjust the position of the wiper.

Re-adjust the position of the wiper.

Replace the presser with the general

presser (presser without knife).

Bobbin thread is taken up on the cloth by

needle thread at 1st stitch at the start of sewing

since needle thread remaining amount after

completion of needle thread clamp is small.

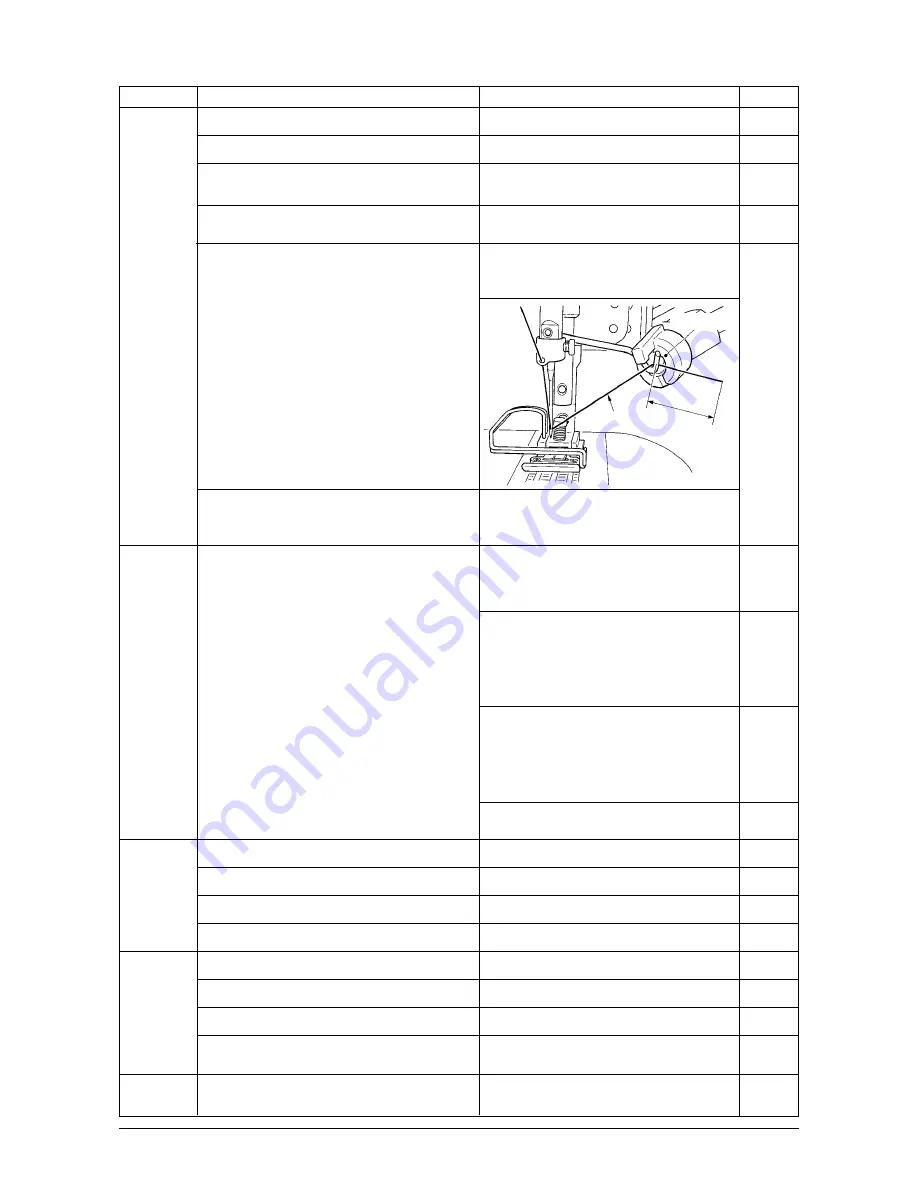

20 to 35 mm

Needle thread

clamp head

Change the kind of thread.

1

Worn-out of needle thread cutting knife.

2

Improper installing position of the knife.

3

Thick thread is used.

4

Start of sewing is set to the reverse feed.

1

Improper UP stop position.

2

Improper wiper locus.

3

Improper wiper position.

4

Length of needle tip is longer than that of the

standard delivery needle.

1

Needle thread enters the needle thread

cutting groove of the presser.

Needle thread

is cut during

sewing.