25

ENGLISH

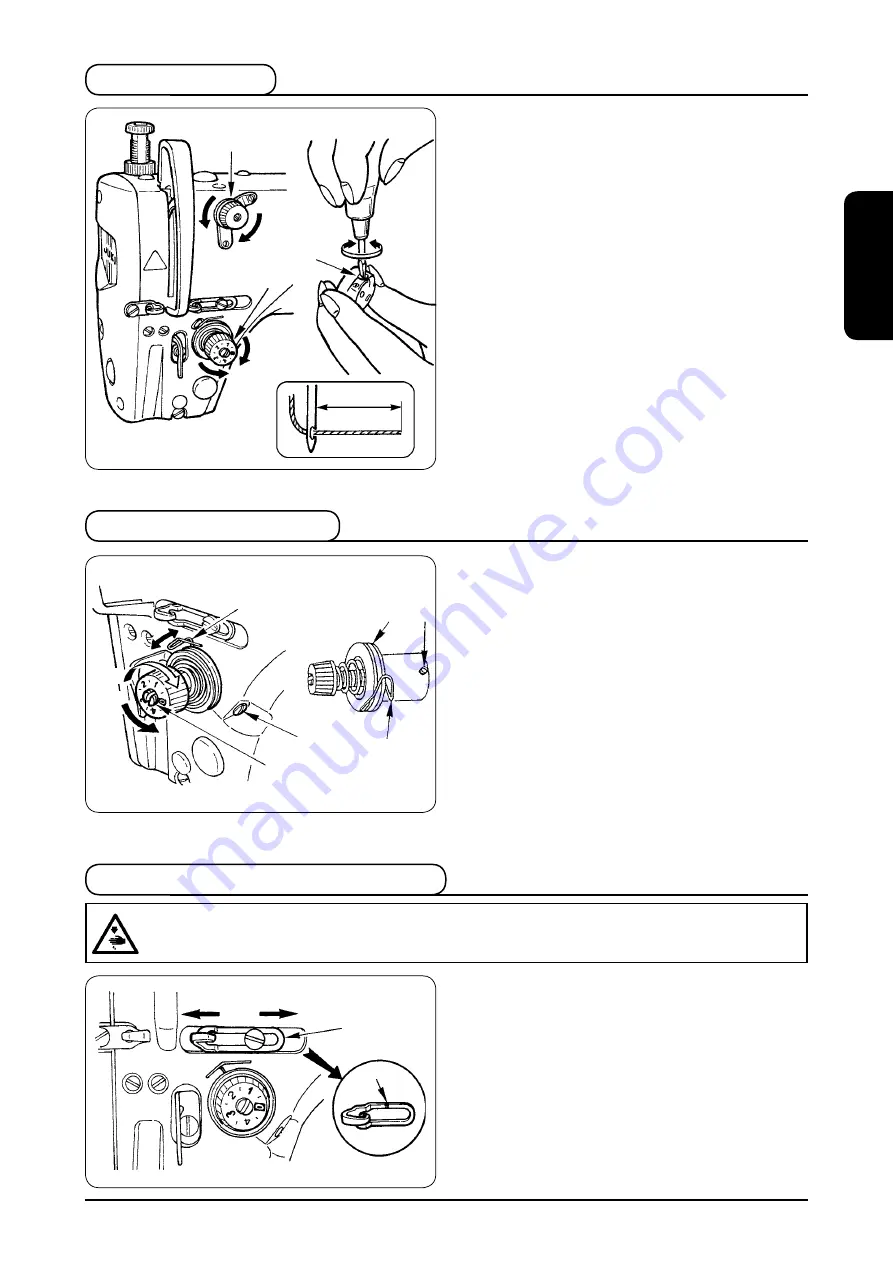

(1) Adjusting the needle thread tension

*

) and 2) are for DLN-6390-7 only.

) As you turn thread tenson No. nut

1

clockwse (n

drecton

A

), the thread remanng on the needle after

thread trmmng wll be shorter.

2) As you turn nut

1

counterclockwse (n drecton

B

),

the thread length wll be longer.

*

Adjust so that the length of the thread remanng on the

needle should be 45 to 50 mm wthn the range where

the thread between the thread tenson No.

1

and the

thread tenson

2

does not move volently.

3) As you turn thread tenson nut

2

clockwse (n drecton

C

), the needle thread tenson wll be ncreased.

4) As you turn nut

2

counterclockwse (n drecton

D

),

the needle thread tenson wll be decreased.

(2) Adjusting the bobbin thread tension

) As you turn tenson adjust screw

3

clockwse (n drecton

E

), the bobbn thread tenson wll be ncreased.

2) As you turn screw

3

counterclockwse (n drecton

F

),

the bobbn thread tenson wll be decreased.

*

Commendable value of bobbn thread tenson s 0.2N.

1

C

2

D

A

B

F

3

E

(1) Changing the stroke of thread take�up spring

1

) Loosen setscrew

2

.

2) As you turn tenson post

3

clockwse (n drecton

A

), the stroke of the thread take-up sprng wll be

ncreased.

3) As you turn the knob counterclockwse (n drecton

B

),

the stroke wll be decreased.

(2) Changing the pressure of thread take�up spring

1

) Loosen setscrew

2

, and remove thread tenson (asm.)

5

.

2) Loosen setscrew

4

.

3) As you turn tenson post

3

clockwse (n drecton

A

),

the pressure wll be ncreased.

4) As you turn the tenson post

3

counterclockwse (n

drecton

B

), the pressure wll be decreased.

) When sewng heavy-weght materals, move thread

gude

1

to the left (n drecton

A

) to ncrease the

length of thread pulled out by the thread take-up.

2) When sewng lght-weght materals, move thread gude

1

to the rght (n drecton

B

) to decrease the length of

thread pulled out by the thread take-up.

3) Normally, thread gude

1

s postoned n a way that

marker lne

C

s algned wth the center of the screw.

7. Theead take�up spring

8. Adjusting the thread take�up stroke

WARNING :

To protect against possible personal injury due to abrupt start of the machine� be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

6. Thread tension

45 to 50 mm

1

5

4

3

2

1

A

B

1

A B

C

Содержание DLN-6390

Страница 2: ......

Страница 3: ... 日本語 日本語 ...

Страница 4: ...ii 日本語 ...

Страница 21: ...10 日本語 3 ひざスイッチの取り付け 1 付属のひざスイッチ 1 をテーブル下面のお好み の位置に木ねじ 2 で固定してください 配線は 2 コードの配線を参照ください 1 2 ...

Страница 55: ... ENGLISH ENGLISH ...

Страница 56: ...ii ENGLISH ...

Страница 63: ...vii ENGLISH ...

Страница 109: ... DEUTSCH DEUTSCH ...

Страница 110: ...ii ...

Страница 117: ...vii DEUTSCH ...

Страница 163: ... FRANÇAIS FRANÇAIS ...

Страница 164: ...ii ...

Страница 171: ...vii FRANÇAIS ...

Страница 217: ... ESPAÑOL ESPAÑOL ...

Страница 218: ...ii ...

Страница 225: ...vii ESPAÑOL ...

Страница 271: ... ITALIANO ITALIANO ...

Страница 272: ...ii ...

Страница 279: ...vii ITALIANO ...

Страница 325: ... 中 文 ...

Страница 326: ...ii ...

Страница 333: ...vii 中 文 ...

Страница 338: ... 1 如图所示那样把线架安装到机台孔上 2 用固定螺母 1 固定线架 3 顶线配线时 请把电源线从线架杆 2 中穿过 线杆接头 请如图所示的那样进行组 装 2 线架的安装 1 2 100 mm 线杆 接头 线杆接头 约 45 ...

Страница 344: ...10 1 用木螺丝 2 把附属的膝动开关 1 安装机台下 面的适当位置 配线请参照 2 电缆线的配线的内容 1 2 3 膝动开关的安装 ...

Страница 352: ...18 2 排油 用螺丝刀卸下螺丝 1 就可以把缝纫机内部的废油从机台下面的孔 A 排出来 使用附属的漏斗 4 的话非常方便 O 形环 2 安装在螺丝 1 和油壶 3 之间 请注意不要丢失 2 1 A 4 ...

Страница 356: ...22 3 上线的穿线方法 注意 为了防止突然的起动造成人身事故 请关掉电源 确认马达确实停止后再进行操作 穿线方法不正确 会造成跳针 断线 张力不好等故障 6390 6390 6390 7 6390 7 ...

Страница 376: ...42 5 电气箱的连接和设定 带切线功能的机针冷却装置的电磁阀电缆线连接到 SC 921 的 CN56 连接器上 请打开 SC 921 电气箱的盖子 参照图 1 进行连接和变更 图 1 CN56 ...

Страница 378: ... 44 ...

Страница 379: ......