– 80 –

0: Up position

28

Needle stop position is set

—

0

1: Upper dead

point

0: Normal

29

Thread trimming can be prohibited

—

0

1: Thread trimming

prohibited

30

Route of return to origin by return to

0: Disabled

origin button can be selected

1: Pattern data

—

0

1

reverse tracing

2: Origin retrieval

→

sewing start position

31

Bobbin winding speed can be set

800 to 2000rpm

100rpm

1600

0: Disabled

32

Motion method of wiper can be selected

—

1

1: Enabled

Unit of sewing shape size change

0: % input

33

can be selected

—

0

Function for IP-410 only

1: Actual size input

34

Thread tension output time when

0 to 20 (1sec)

1sec

0

needle thread tension setting can

(0: No thread

be set

tension output)

35

Bend position of thread clamp is

0: S type

1

S type: 0/H type: 1

selected

1: H type thin thread

(#50 to #8)

2: H type intermediate

3: H type thick threas

(#5 to #2)

No.

Item

Setting range

Initial value

HL

HS

SL

HL

HS

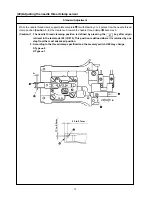

2516

2516

2516

2516

3020

FU06

*

SS

2516

*

SS

3020

*

SL

2516

FU06

S m a l l e s t

changeable

unit

Содержание AMS-221EHL

Страница 185: ... 181 A JUKI Grease A B JUKI Grease B C Grease A A A A A A A B C C B B B B o MAIN SHAFT NEEDLE BAR COMPONENTS ...

Страница 190: ... 186 o X Y COMPONENTS 1 E C C C C C Grease E Three Bond 3060G Locktight 241 ...

Страница 191: ... 187 o X Y COMPONENTS 2 D D C C C D C C D C Grease D Grease D Locktight 241 ...

Страница 192: ... 188 C Grease D Grease D D C D C C D C D D C C D D D D D C D C o CLOTH FEED MECHANISM COMPONENTS D ...

Страница 231: ... 7 MAIN PANEL board circuit diagram 227 PANEL BOARD MAIN BOARD ...