– 72 –

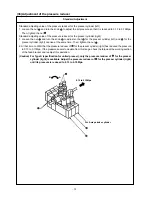

When the needle thread clamp support plate complete

is withdrawn by 3 to 4 pulses from the needle thread

clamp position (Caution 1., 2.) the clearance A toward the needle thread clamp

becomes 0.

(Caution) 1. The needle thread clamping position is defined by pressing the key after origin

retrieval in the test mode I08 (IP-410). This position is defined where it is returned by one

step from the most advanced position.

2. According to the thread clamp specifications, the memory switch U69 may change.

S Type

→

→

→

→

→

0

H Type

→

→

→

→

→

1

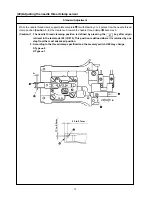

(49) Adjusting the needle thread clamp sensor

Standard Adjustment

C

B

A

3.3 to 3.7mm

1.7 to 2.3mm

Содержание AMS-221EHL

Страница 185: ... 181 A JUKI Grease A B JUKI Grease B C Grease A A A A A A A B C C B B B B o MAIN SHAFT NEEDLE BAR COMPONENTS ...

Страница 190: ... 186 o X Y COMPONENTS 1 E C C C C C Grease E Three Bond 3060G Locktight 241 ...

Страница 191: ... 187 o X Y COMPONENTS 2 D D C C C D C C D C Grease D Grease D Locktight 241 ...

Страница 192: ... 188 C Grease D Grease D D C D C C D C D D C C D D D D D C D C o CLOTH FEED MECHANISM COMPONENTS D ...

Страница 231: ... 7 MAIN PANEL board circuit diagram 227 PANEL BOARD MAIN BOARD ...