– 49 –

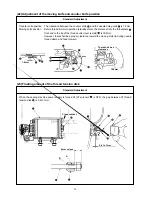

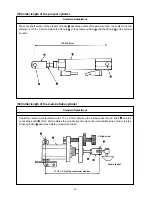

1. Align the Y drive shaft thrust collar

with the flat section of the Y

drive shaft

. Then, tighten two setscrews

.

2. Lightly press the Y drive shaft thrust collar

in Direction A, and also

the Y drive sprocket A

in Direction B. Since then, tighten 2 setscrews

.

At that time, 1 of the setscrews

should be aligned with the flat

section of the Y drive shaft

.

(Caution) Confirm that there is no rattling in axial direction in the

Y drive shaft

.

3. Separate the Y drive sprocket B

by 1mm from the processed face

of the bed and stop it. Then, tighten 2 setscrews

.

At that time, 1 of the setscrews

should be aligned with the flat

section of the Y drive shaft

.

o If there is any rattling, this can be

a cause of feed error.

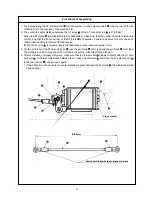

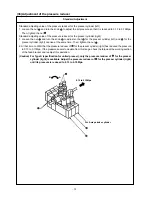

1. Loosen 4 setscrews

.

2. Move the X movement base

forward and backward two or three

times.

3. Tighten 4 setscrews

.

* When the Y timing belt

is adjusted, phase adjustments of this Y

timing belt

should be carried out, without fail.

(Caution) If the Y timing belt

is kept contact with the Y movement

base

, phase adjustments cannot be carried out even

though the Y movement base

is moved forward and

backward.

o Incorrect phase matching can be

a cause of feed error.

Adjustment Procedures

Results of Improper Adjustment

Adjustment Procedures

Results of Improper Adjustment

Содержание AMS-221EHL

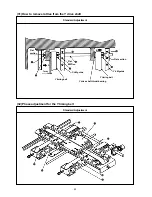

Страница 185: ... 181 A JUKI Grease A B JUKI Grease B C Grease A A A A A A A B C C B B B B o MAIN SHAFT NEEDLE BAR COMPONENTS ...

Страница 190: ... 186 o X Y COMPONENTS 1 E C C C C C Grease E Three Bond 3060G Locktight 241 ...

Страница 191: ... 187 o X Y COMPONENTS 2 D D C C C D C C D C Grease D Grease D Locktight 241 ...

Страница 192: ... 188 C Grease D Grease D D C D C C D C D D C C D D D D D C D C o CLOTH FEED MECHANISM COMPONENTS D ...

Страница 231: ... 7 MAIN PANEL board circuit diagram 227 PANEL BOARD MAIN BOARD ...