Component Testing

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

16021730 Rev. 0

5

Component

Description

Test Procedures

Condenser

Condenser is a tube and fin construction

located in machine compartment.

Condenser is on high-pressure discharge

side of compressor. Condenser function

is to transfer heat absorbed by refrigerant

to ambient.

Higher-pressure gas is routed to

condenser where, as gas temperature is

reduced, gas condenses into a high-

pressure liquid state. Heat transfer takes

place because discharged gas is at a

higher temperature than air that is

passing over condenser. It is very

important that adequate airflow over

condenser is maintained.

Condenser is air cooled by condenser

fan motor. If efficiency of heat transfer

from condenser to surrounding air is

impaired, condensing temperature

becomes higher. High liquid temperature

means liquid will not remove as much

heat during boiling in evaporator as

under normal conditions. This would be

indicated by high than normal head

pressures, long run time, and high

wattage. Remove any lint or other

accumulation that would restrict normal

air movement through condenser.

From condenser the refrigerant flows into

a post condenser loop which helps

control exterior condensation on flange,

center mullion, and around freezer door.

Refrigerant the flows through the drier to

evaporator and into compressor through

suction line.

Leaks in condenser can usually be detected by using an electronic leak detector

or soap solution. Look for signs of compressor oil when checking for leaks. A

certain amount of compressor oil is circulated with refrigerant.

Leaks in post condenser loop are rare because loop is a one-piece copper tube.

For minute leaks

1. Separate condenser from rest of refrigeration system and pressurize

condenser up to a maximum of 235 PSI with a refrigerant and dry nitrogen

combination.

2. Recheck for leaks.

Refrigerator light

switch

Single pole, single throw switch

completes circuit for light when door is

open.

Check resistant across terminals.

Switch arm depressed

“NO” terminals

Open

Switch arm up

“NO” terminals

Closed

Thermostat

Thermostat is in a series circuit with

terminal 2 of defrost timer, and defrost

heater. Circuit is complete if evaporator

fan motor operates when cold.

Controls the circuit from freezer

thermostat through defrost terminator to

defrost heater. Opens and breaks circuit

when thermostat senses preset high

temperature.

Test continuity across terminals.

With power off and evaporator coil below freezing, thermostat should show

continuity when checked with ohmmeter. See “Heater, evaporator (defrost)”

section for additional tests.

After defrost thermostat opens, thermostat remains open until end of defrost

cycle and refrigerator starts cooling again. Defrost thermostat senses a preset

low temperature and resets (closes).

WARNING

!

To avoid severe personal injury or death from sudden eruption of high

pressures gases, observe the following:

Protect against a sudden eruption if high pressures are required for leak

checking.

Do not use high-pressure compressed gases in refrigeration systems

without a reliable pressure regulator and pressure relief valve in the

lines.

Содержание Luxury Series

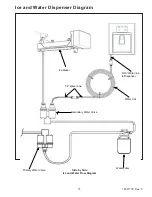

Страница 13: ...13 16021730 Rev 0 Refrigerant Flow Side by Side Refrigerant Flow Diagram ...

Страница 14: ...16021730 Rev 0 14 Cabinet Air Flow Side by Side Cabinet Air Flow Diagram ...

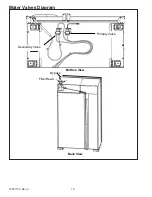

Страница 16: ...16021730 Rev 0 16 Water Valves Diagram Bottom View Back View Primary Valve Secondary Valve Filter Head Bypass ...

Страница 46: ...A 1 ...

Страница 72: ...B 1 Appendix B ...