40

TROUBLESHOOTING

-

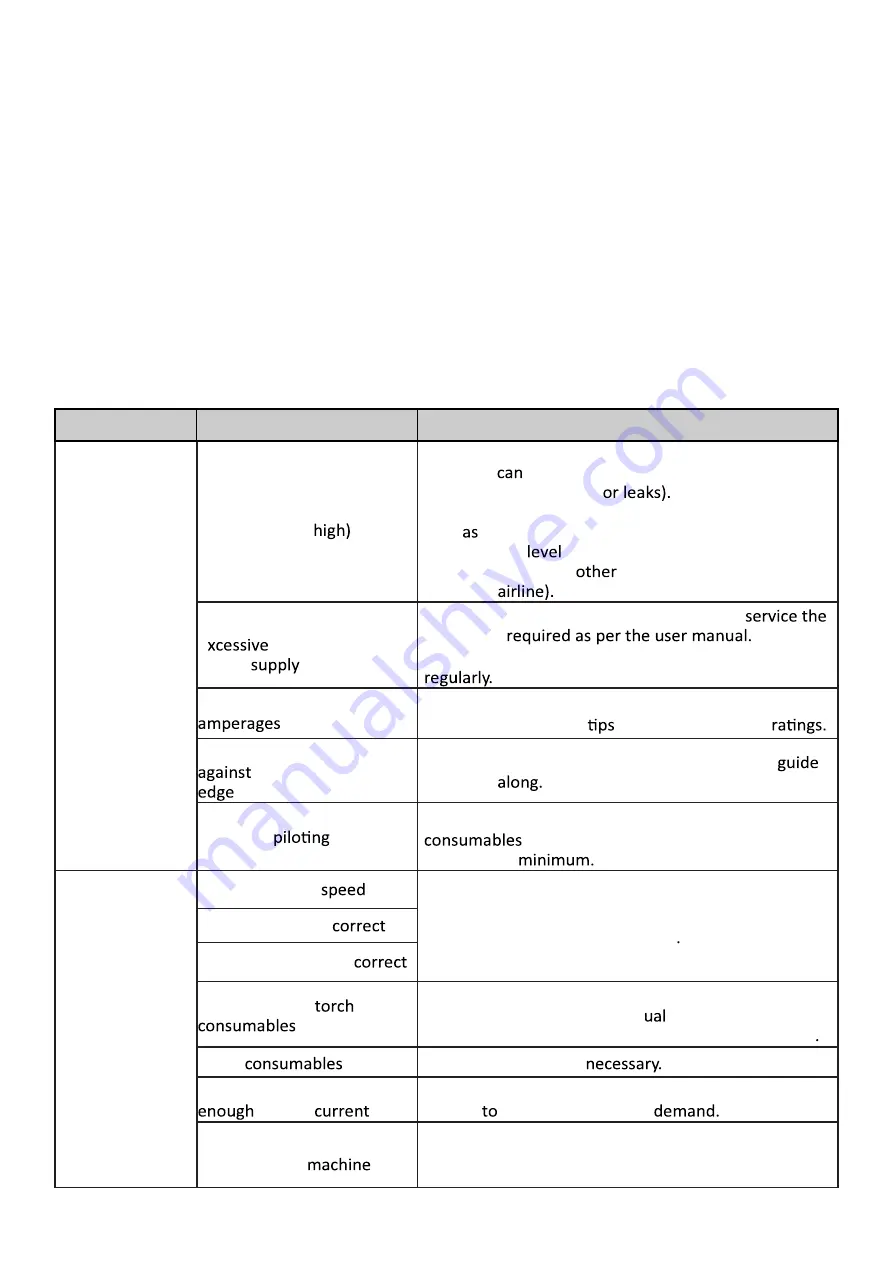

PLASMA CUTTING PROBLEMS

The proper installation, application and operation of plasma arc cutting equipment can save many man

hours and reduce costs which will give you the promised cut quality and longer consumable parts life.

Cut quality issues or poor consumable life are generally the most experienced problems seen with plasma

cutting systems and more often than not are caused by the same thing, for example, low or too high air

pressure, low air flow, water or oil in the supply airline will all give you poor cut quality and premature

consumable wear. It

’

s often difficult to diagnose cutting issues without understanding the machines use

and setup and there are various questions that need to be asked to be able to give the best advice.

Below is listed a few pointers to help you on your way to obtaining consistently good cut quality:

•

Ensure your mains power supply is suited to the plasma cutting machines specifications.

•

Ensure the supplied gases or air supply is in keeping with the requirements of the plasma machine.

•

Ensure your plasma machines amperage setting matches the amperage of the cutting tips.

•

Clean and service the plasma machine and torch regularly, it is important that the operator watch the

torch for signs of contamination or worn consumables being used.

Excessive use

of consumables

(short life time

of consumables)

Low air pressure or low

air flow (or too

Check for low air pressure to the plasma machine

(low flow

be caused by a long air hose with a

small internal diameter

Ensure your compressor is set to deliver the correct

CFM

detailed in the plasma owner

’

s manual and

can keep this

maintained during your cutting

operation (consider

equipment being used on

the same

Contaminated gas or

e

moisture in

the air

Use suitable airline filters or air dryers and

devices as

If using a compressor, ensure the receiver is drained

Drag cutting at high

Refer to the torch spare parts of this manual for the

correct use of cutting

and their amperage

Dragging the cutting tip

a metallic straight

Ensure you use a non

-

metallic straight edge to

the torch

Excessive

Keeping the pilot arc maintained will erode the

much faster than when cutting, keep

piloting to a

Poor cut

quality

Improper travel

Check the cutting guide chart (page 37) for the correct

settings for the material being cut

Cutting amps not

Stand

-

off height not

Using incorrect

Refer to the plasma spare parts breakdown on

from page 34 of this user man

for the correct

consumable configuration for the application

Worn

Check and replace as

Plasma not delivering

output

Have a technician check the output current of the

plasma

ensure it is meeting

Incorrect air pressure or

air flow to the

Check machines air demand specifications, refer to

page 13 within this user manual to ensure the air

supply meets the minimum requirements.

Problem

Possible cause

Suggested action

Содержание EVO 2.0 EP-45

Страница 1: ...1 ClearVision Optional TFT LCD screen included...

Страница 44: ...44 UKCA Declaration of Conformity...

Страница 45: ...45 EC DECLARATION OF CONFORMITY...

Страница 50: ...50...