38

TROUBLESHOOTING

The following operation requires sufficient professional knowledge on electric aspects and

comprehensive safety knowledge. Make sure the input cable of the machine is disconnected

from the electricity supply and wait for 5 minutes before removing the machine covers.

Before any welding and cutting machines are dispatched from the factory, they have already been

checked thoroughly. The machine should not be tampered with or altered. Maintenance must be carried

out carefully. If any wire becomes loose or is misplaced, it maybe potentially dangerous to the user!

There are dangerous voltages present within this plasma power supply unit. Only professionally trained

maintenance personnel should repair the machine!

Ensure the power is disconnected before working on the machine. Always wait 5 minutes after power

switch off before removing the panels.

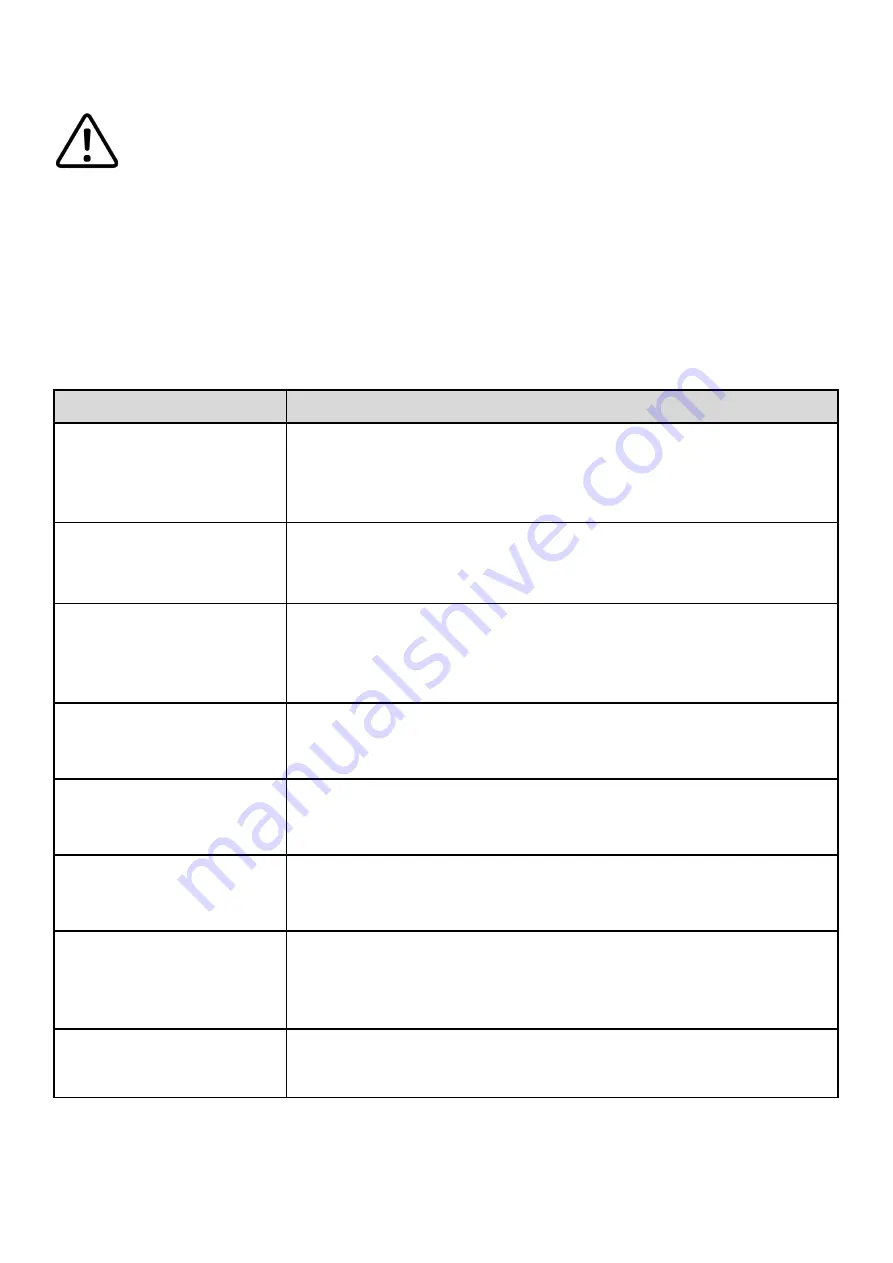

Description of fault

Possible cause

Mains power switch is on,

although the power indicator

doesn

’

t light up.

Check input power that it is turned on.

Check the input power fuse.

Check the input cable plug and connections.

Check the ON/OFF switch for function and continuity.

Primary power switch is on,

but the cooling fan does not

work.

Check fan is not being blocked by debris.

Check fan for functionality.

Check fan supply.

No air flow at torch when

either torch trigger is pressed

or air purge switch is

activated.

Check the compressor.

Check all the input air connections and fittings.

Internal connection is disconnected or loose.

Check the purge switch for functionality.

Overheat error code is lit.

Machine operated outside duty cycle, allow the machine to cool and

the unit will reset automatically.

Fan not working

-

check for obstruction blocking the fan.

Nothing happens when

plasma torch switch is closed

Check and test the plasma torch and leads (switch circuit

Pilot arc does not initiate

when the torch switch is

activated.

Gas pressure too low to the machine.

The pilot arc extinguishes

soon after igniting

Check and replace the torch consumables.

Check and adjust the air pressure.

Check and if required drain any water build up in the filter cup of the

regulator on the rear panel.

Pilot arc is ON but the cutting

arc will not establish

Work cable not connected to work piece or damaged/broken.

Check and replace the torch consumables.

Содержание EVO 2.0 EP-45

Страница 1: ...1 ClearVision Optional TFT LCD screen included...

Страница 44: ...44 UKCA Declaration of Conformity...

Страница 45: ...45 EC DECLARATION OF CONFORMITY...

Страница 50: ...50...