37

CUT QUALITY

Dross

The formation of dross on the bottom of the plate can be caused when cutting parameters such as

speed, amperage, arc voltage, gas pressure/flow and type of gas are not correct for the metal type and

thickness being cut.

Most commonly, incorrect cutting speeds are to blame for excessive dross. High cutting speeds can

results in high speed dross that can be very hard to remove without grinding. Low speed dross can be

easily removed with a brush or chip hammer.

Top edge rounding

This is when the top edge of the cut face has eroded away and is not square which is created from the

plasma cutting process. It is generally caused when cutting with excessive current or standoff distance.

This can be a common occurrence when cutting thick materials.

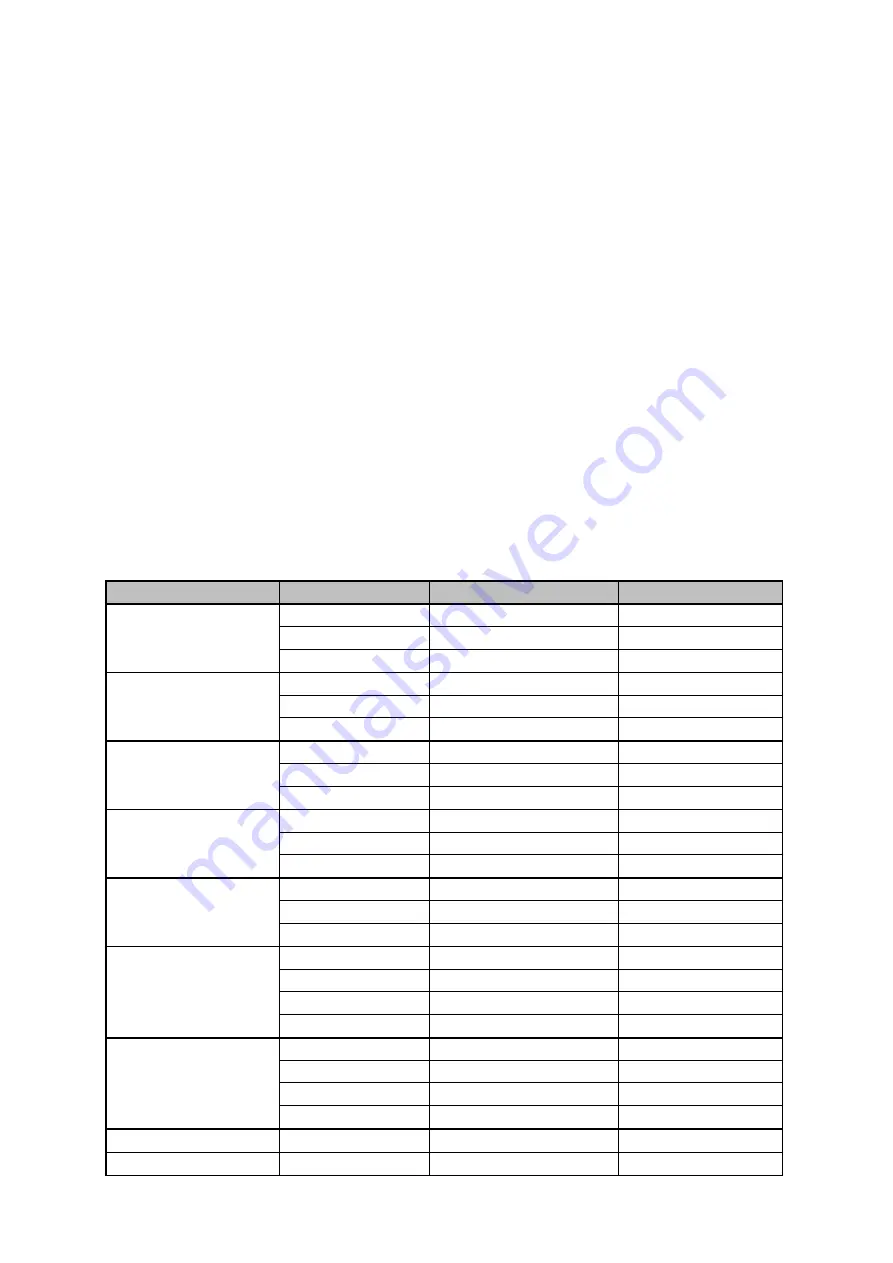

TYPICAL CUTTING SPEEDS

Cutting speeds can vary according to power source output, cutting table quality, material thickness along

with material type being cut as well as the operators skill set.

Speeds shown below are offered as a guide only for our Jasic hand cutting systems using compressed

air, cutting mild steel material with the stated output currents ensuring that the cutting tip fitted matches

the stated amperages.

Note: The above chart is a guide as many factors can distort cutting chart figures when hand cutting.

Material Thickness

Amperage

Speed mm/m

Air Pressure

40

5000

-

6000

5 bar / 73psi

1mm

60

6200

-

7000

5 bar / 73psi

80

7200

-

8000

5 bar / 73psi

40

1800

-

2600

5 bar / 73psi

3mm

60

3200

-

4200

5 bar / 73psi

80

3800

-

4600

5 bar / 73psi

40

800

-

1100

5 bar / 73psi

6mm

60

1200

-

2000

5 bar / 73psi

80

1800

-

2500

5 bar / 73psi

40

200

-

300

5 bar / 73psi

12mm

60

400

-

650

5 bar / 73psi

80

650

-

820

5 bar / 73psi

60

400

-

500

5 bar / 73psi

15mm

80

450

-

540

5 bar / 73psi

100

750

-

880

5 bar / 73psi

60

280

-

340

5 bar / 73psi

20mm

80

380

-

450

5 bar / 73psi

100

400

-

480

5 bar / 73psi

120

650

-

750

5 bar / 73psi

25mm

80

180

-

210

5 bar / 73psi

100

200

-

240

5 bar / 73psi

120

300

-

380

5 bar / 73psi

160

400

-

480

5 bar / 73psi

30mm

160

320

-

400

5 bar / 73psi

45mm

160

230

-

350

5 bar / 73psi

Содержание EVO 2.0 EP-45

Страница 1: ...1 ClearVision Optional TFT LCD screen included...

Страница 44: ...44 UKCA Declaration of Conformity...

Страница 45: ...45 EC DECLARATION OF CONFORMITY...

Страница 50: ...50...