26

INSTALLATION

Input Power Connection continued

Warning!

1.

Test with multi

-

meter to ensure the input voltage value is within the specified input voltage range.

2.

Ensure that the power switch of the welder is turned off.

3.

Wire the input mains cable wires to the correct sized mains plug, ensuring that the live, neutral and

earth (ground) wires are connected correctly.

4.

Carry out an electrical test of the machine if required (i.e. PAT test)

5.

Ensure that the mains supply fusing is correctly rated for the machine.

6.

Connect the machine mains power plug firmly to the corresponding supply socket.

Please Note!

If the machine needs to be operated on long extension leads, then please use an extension lead where

the cable has a larger cross

-

sectional area to reduce the voltage drop, please consult your electrician or

electrical supplier for the recommended size.

Input air connection

•

The Jasic EVO EP

-

45 and EP

-

45SC Plasma machines are only designed to be used with a reliable,

consistent supply of clean, dry compressed air which is essential for correct operation.

The EP

-

45SC version can utilizes its own

‘

internal

’

compressed air supply system.

•

D

o not use with oxygen or any other gas.

•

Ensure your compressor offers only dry compressed air and is capable of delivering the volume of air

that is required to run your plasma cutting machine to specification. We recommend the minimum air

supply requirements of 170 Ltr/min @ 5 Bar (75psi). The compressor or air cylinder air requirements

are as follows:

Minimum air input: 5 Bar (75psi)

Maximum air input: 6 Bar (87psi)

Minimum air flow: 6CFM (170Ltr/min)

•

It is recommended the compressed air supply should have an external filtration device installed in the

line supplying the machine, including a water trap and filter

•

Connect the compressed air with the supplied air hose and air fitting to the machine via the inlet

connection on the rear panel (max 8 Bar).

•

The air regulator for the EP

-

45 and EP

-

45SC units is mounted on the rear panel and is adjustable.

•

Any water which has been collected by the air regulator will be drained by the auto drain system of

the inbuilt air regulator.

•

When using either a compressed air cylinder or a compressor ,ensure it is equipped with a suitably

fitted high pressure regulator capable of reducing the pressure to the required amount.

USER SETUP

Output connections

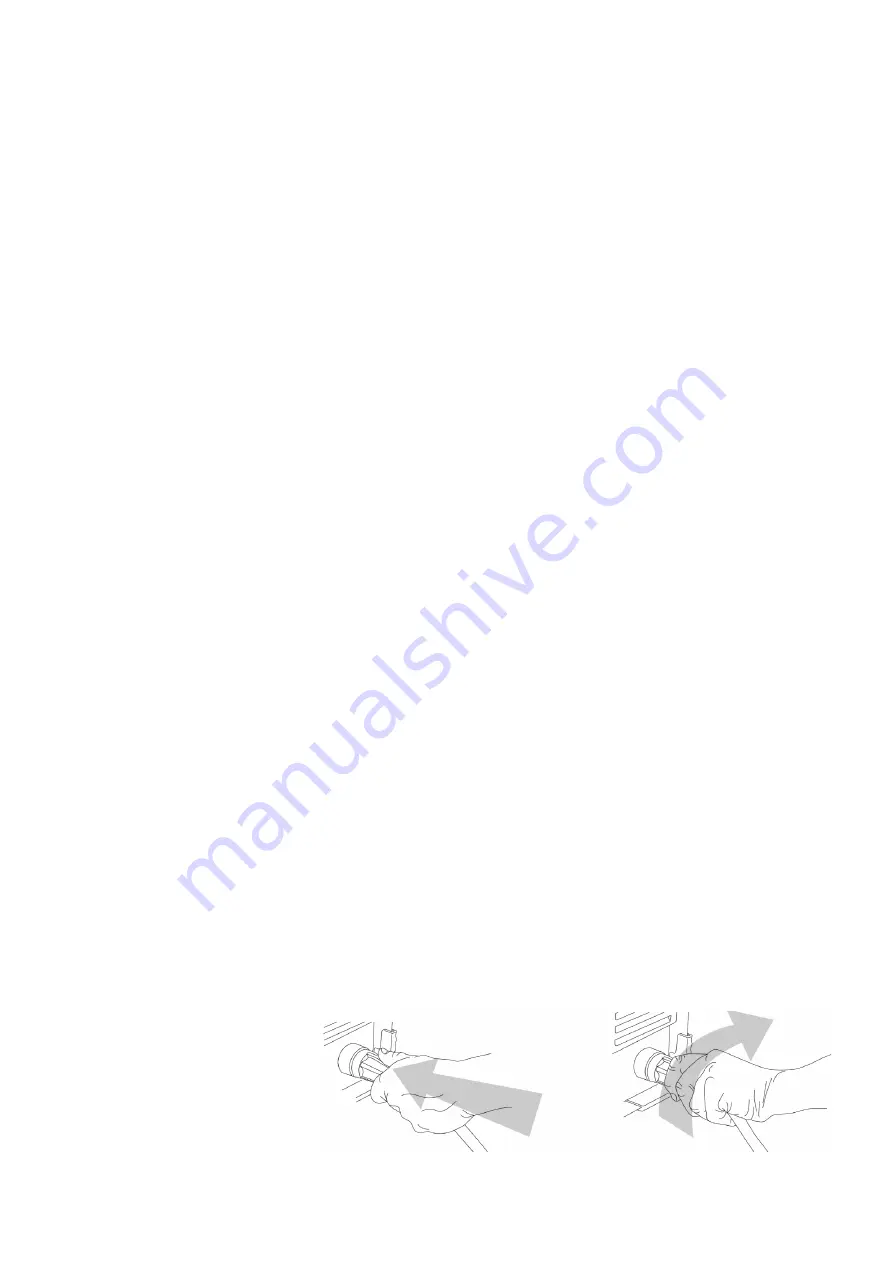

Work return cable

Insert the cable plug of the work

return lead into the dinse socket

on the front panel of the welding

machine and tighten it clockwise.

Check this power connections daily

to ensure they have not become loose otherwise arcing may occur when used under load.

Содержание EVO 2.0 EP-45

Страница 1: ...1 ClearVision Optional TFT LCD screen included...

Страница 44: ...44 UKCA Declaration of Conformity...

Страница 45: ...45 EC DECLARATION OF CONFORMITY...

Страница 50: ...50...