11

WHAT IS PLASMA?

•

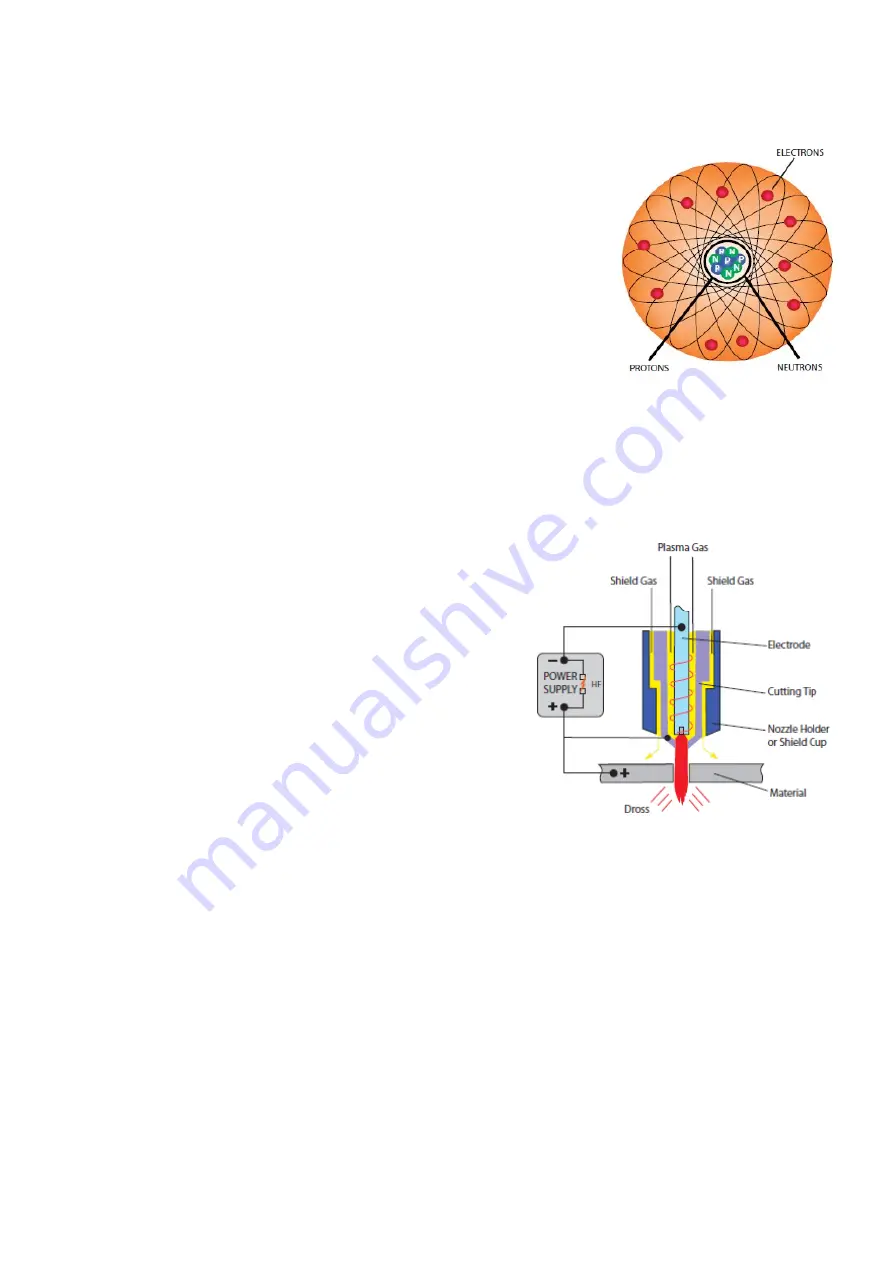

Plasma is commonly described as the fourth state of matter (i.e. solid, liquid, gas then plasma).

•

If you increase gas to an extremely high temperature you get the fourth

state plasma, the energy begins to break apart the gas molecules and

the atoms begin to split. Normal atoms are made up of protons and

neutrons in the nucleus surrounded by a cloud of electrons. In plasma,

the electrons separate from the nucleus. Once the energy of heat

releases the electrons from the atom, the electrons begin to move

around quickly.

The electrons are negatively charged and they leave behind their

positively charged nuclei. These positively charged nuclei are known as

ions. When the fast

-

moving electrons collide with other electrons and

ions, they release vast amounts of energy.

This energy is what gives plasma its unique status and unbelievable cutting power.

•

Plasma is a gas which has been heated to an extremely high temperature and ionized so that it

becomes electrically conductive. An example of naturally occurring plasma is lightning.

•

The plasma arc cutting, gouging and welding processes uses plasma to transfer an electrical arc to

the work piece, the electrically conductive gas will transfer the energy from the plasma power source

through a plasma torch to the material being cut.

•

The plasma arc cutting process basics can be seen in the

illustration. The basic principle is that the arc is formed

between the electrode and the work piece by forcing the

plasma gas and the electrical arc through a small orifice

within the copper tip. This will increase the speed and

temperature of the plasma exiting the tip. The temperature

of the plasma is in excess of 15000°C and the speed can

approach that of sound. This plasma gas flow in conjunction

with the high temperature enables a deeply penetrating

plasma jet to cut through the work piece material and at

the same time molten material is blown away from the cut.

•

The process differs from the oxy

-

fuel process in that the plasma process works by using the high

temperature arc to melt the metal to be cut.

With the oxy

-

fuel process, the oxygen oxidises the metal to be cut and the heat from the exothermic

reaction melts the metal. So, unlike the oxy

-

fuel process, the plasma process can be used to cut

metals including those which form protective refractory oxides such as aluminium, stainless steel,

non

-

ferrous alloys and cast iron.

•

The output current (amps) of the power supply will determine the cutting thickness and speed

capabilities of the plasma machine.

•

While the primary goal of plasma arc cutting is the separation of metal, plasma arc gouging is used

to remove metals to a controlled depth and width.

•

Plasma machines consist of a power supply, an arc starting circuit, a plasma torch and a compressed

air supply.

•

Direct current (DC) straight polarity is used for plasma cutting with the electrode being

-

negative

and the tip/work piece being + positive.

Содержание EVO 2.0 EP-45

Страница 1: ...1 ClearVision Optional TFT LCD screen included...

Страница 44: ...44 UKCA Declaration of Conformity...

Страница 45: ...45 EC DECLARATION OF CONFORMITY...

Страница 50: ...50...