Jabiru Aircraft

Pty Ptd

Aircraft Service Manual

Jabiru J230-C

REVISION

0

Dated : Feb 2006

Issued By: RAS

Page: 135 of 171

L:\files\Technical_manuals\J230_J430\J230.J430_Work_files\J230-C_Tech_Rev_1.doc

Print Date: 14/01/2009 4:41:00 PM

13.3.1

PITOT – STATIC SYSTEM MAINTENANCE

Proper maintenance of pitot and static system is essential for proper operation of the

altimeter, airspeed indicator and vertical speed indicator (if fitted). Leaks, moisture and

obstructions in the pitot system will result in false airspeed indications, while static system

malfunctions will affect readings of all three instruments. Cleanliness and security are the

principal rules for system maintenance. The pitot tube and static ports MUST be kept

clean and unobstructed.

13.3.1.1

PITOT-STATIC WATER TRAPS

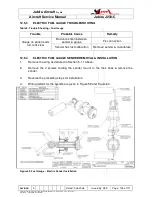

Figure 55 shows the general layout of the pitot-static system. The water trap for the static

system is located inside the ventral fin (the faring under the tail which covers the trim

mechanism). The water trap for the pitot system is located inside the fairing at the lower

end of the wing strut. Both traps should be inspected and, if necessary, drained during

scheduled maintenance. In addition, if the aircraft is parked, flown or otherwise exposed to

rain or moisture, the water traps should be checked and, if necessary, drained.

13.3.2

STATIC PRESSURE SYSTEM INSPECTION & LEAKAGE TEST

The following procedure outlines inspection and testing of the static pressure system,

assuming that the altimeter has been tested and inspected in accordance with the current

Regulations.

1.

Ensure the static system is free from entrapped moisture and restrictions. Refer to

2.

Ensure no alternations of airframe surface have been made which would effect the

relationship between air pressure in the static pressure system and truce ambient

static air pressure for any flight configuration.

3.

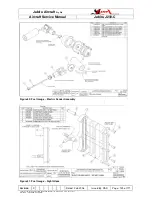

Attach a source of suction to static pressure source opening. Figure 58 shows one

method of obtaining suction.

4.

Slowly apply suction until the altimeter indicates a 1000-foot increase in altitude.

CAUTION

When applying or releasing suction, do not exceed the range of either vertical

speed indicator or airspeed indicator.

5.

Cut off suction source to maintain a “closed” system for one minute. Leakage shall

not exceed 100 feet altitude loss as indicated on the altimeter.

6.

If leakage rate is within tolerance, slowly release suction source.

NOTE:

If leakage rate exceeds maximum allowable, first tighten all connections, then repeat

leakage test. If leakage rate still exceeds maximum allowable use the following

procedure:

1.

Disconnect static pressure lines from airspeed indicator and vertical speed

indicator.