Remote Control System TT801 – User Guide

MU-TT801-AN rev.6 September 2009

56

System:

PET801P, PET661S-TT and

interconnect cable

Preventive Maintenance

Sub-system:

Dunking Transducer

Reference

: PM02

Page

: 1/1

Subject:

Inspection and Cleaning

Transducer Neoprene boot and cable

Maintenance level:

1

Periodicity:

after and before each deployment

Duration:

10 minutes

The neoprene boot of the transducer should always be free of grease or oil prior to

immersion. The interconnect cable must be fully watertight at least for the section

deployed in the water.

High voltage may exist at both leads of any piezoelectric transducer. It is recommended to

short circuit pin

K

and

M

of the SOURIAU 851 08 EC 14-12 P 50 44 mating plug.

For cleaning use a soapy solution with soft cloth or sponge. Do not use alcohol or

petroleum solvents.

Transducer should not be connected to the TT801 cabinet.

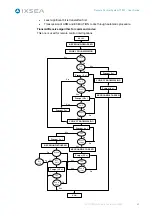

Step Action

1.

Acoustic Transducer:

•

Immediately after recovery from water, rinses and washes in fresh water.

•

Check the neoprene boot is not squashed, split or punctured.

•

Check top oil filling screw is in place and absence of oil leakage.

•

Get rid of any dust and clean the neoprene boot with a soapy solution to remove

trace of grease, oil or contaminants.

If relevant, check the bulkhead connector of the transducer: clean the interior and install

a dummy plug before storage.

2.

Interconnect cable between transducer and TT801 cabinet:

•

Immediately after recovery from water, rinses and washes the cable jacket in fresh

water. Take care to get free of water the cable connector(s). Then dry the cable with

a soft cloth or sponge.

•

Check the cable jacket is not squashed, split.

Check the connector(s) of cable are fully functional.

3.

End of procedure.

Cautions and

hazards

Requirements

Pre-

Requisites

Procedure

Содержание TT801

Страница 1: ...TT801 Remote Control System User Guide...

Страница 2: ......