Throughout this section on bearing lubrication, different pumpage temperatures are listed. If the

equipment is ATEX certified and the listed temperature exceeds the applicable value shown in the table

under ATEX identification, then that temperature is not valid. Should this situation occur, please consult

with your ITT/Goulds representative.

For ATEX applications bearing replacement (all) is recommended after 50,000 hours of operation.

6.1.3.1 Oil Lubricated Bearings

1.

Remove the bearing housing breather (113A) and add oil until oil level is at the center of the sight

glass.

2.

If the unit has an external oil lube system, fill the bearing housing and the reservoir to satisfy the

system requirements.

3.

Replace the breather.

Refer to Oil Volume table for required oil volume.

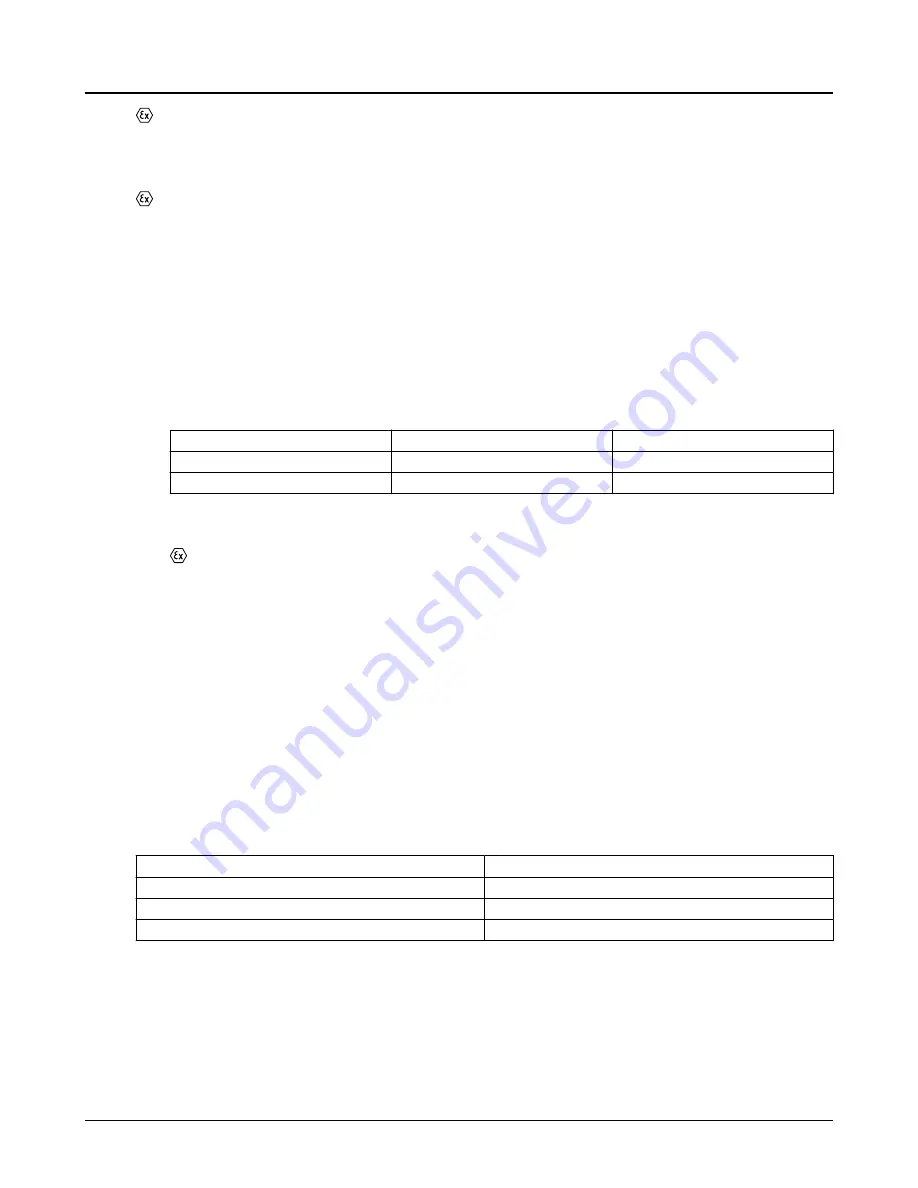

Table 7: Axial Flow Pump Approximate Oil Volume

Pump Size

Quarts

Litres

42" / 1200mm / 54"

74

70.5

60" / 66"

62

59

Approximate values only. Always fill using sight glass to verify level. Oil level should be at the center

of the sight glass. See comments in this section.

Bearings must be lubricated properly in order to prevent excess heat generation, sparks and

premature failure.

4.

Run the pump for 1 minute to fill the oil galleys and in and around each bearing. Check the sight

glass and add oil accordingly. Monitor the oil level indicator for the first 24 hours of operation and

maintain fill level.

6.1.3.2 Acceptable oil for lubricating bearings

A good SAE#30 or #40 is usually satisfactory. Consult a reputable supplier for acceptable substitutes for

the oils mentioned. The viscosity of the oil should be 150 SSU at the operating temperature to prevent

accelerated bearing wear 66°C | 150°F is the maximum temperature at which a typical 30 wt. oil will sup-

ply the required viscosity.

A good SAE#30 or #40 is usually satisfactory. Consult a reputable supplier for acceptable substitutes for

the oils mentioned. The viscosity of the oil should be 150 SSU at the operating temperature to prevent

accelerated bearing wear 66°C | 150°F is the maximum temperature at which a typical 30 wt. oil will sup-

ply the required viscosity.

Operating temperature

Oil requirement

below 66°C | 150°F

SAE 30

66-71°C | 150-160°F

SAE 40

71-82°C | 160-180°F

SAE 50

An oil with a higher viscosity than required will increase the bearing operating temperature because of

the extra viscous drag, but never to the point where the viscosity becomes lower than required from the

increased heat generation. It is therefore better for the bearings to have an oil that is too heavy rather

than too light.

Change the oil after the first 200 hours of operation. For normal operating conditions, change the oil at

least four (4) times a year. If the bearing assembly is exposed to dirty or moist conditions, the oil should

be changed more often.

6.1 Maintenance

Model AF (42"/1200mm/54"/60"/66") LM/LMR Bearings Installation, Operation, and Maintenance Manual

47