87

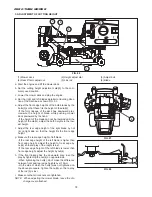

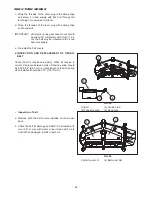

3. INSPECTION & REPLACEMENT OF BLADES

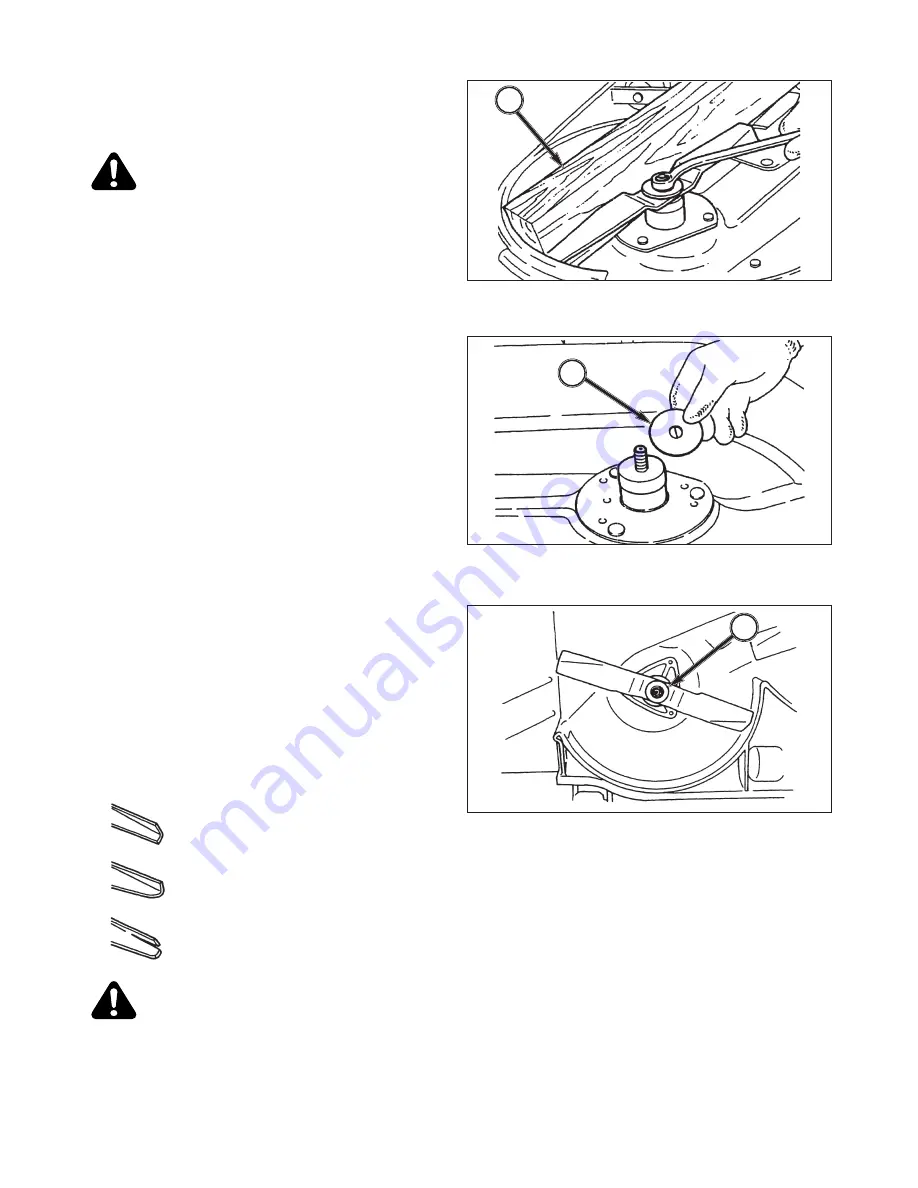

Blade Removal

CAUTION: Be sure to wear gloves to avoid

cuts by blades.

Block blades by inserting a piace of wood,1, between

blade and mower deck. Loosen blade retaining nut with a

27-mm box end wrench. As blades are tightened with

washers and shims, take care not to lose them when

blades are disassembled.

Shimming of Blades

Tighten blade nuts temporarily to determine the height

difference between blades. If more than 0.04" (1mm), cor-

rect with adjusting shims,2, Excessive difference in blade

positioning will result in poor mowing finish.

Blade nuts,3, should be tightened to a torque of 94 ft.lbs.

(1300 kgf

・

cm).

IMPORTANT:

•

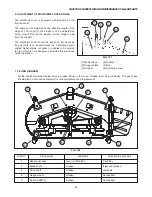

If the blade ends have become round due to wear,

enlarged clearance between blades leave uncut grass

behind. The blade should be checked timely and worn

ones should be replaced immediately.

•

Low cutting height or the operation just after soil has

been applied will wear blades rapidly. The blades

should be checked more frequently.

a. New Blade

b. Blade with rounded edge

c. Exessively worm blades are very dan-

gerous. So replace such blades with

new ones at once.

CAUTION: When sharpening blade edges,

both ends should be done in same manner or

blade becomes unbalanced.

Pass a rod through blade center hole and

check to see if blade is balanced properly. If

balabce is improper, correct it. Unbalansed

blades will cause excessive vibration.

(1) Wood

(2) Shims

(3) Nut

1

2

3

FIG. 103

FIG. 104

FIG. 105

CHAPTER 5. INSPECTION AND MAINTENANCE OF MAJOR PARTS

Содержание SZ330

Страница 1: ...I S E K I Z E R O T U R N M O W E R ZERO TURN MOWER MOWER DECKS SZ330 SSM60 SSM72 ...

Страница 21: ...20 9 29 Check that all safety devices are in place and oper ating properly ZERO TURN MOWER ...

Страница 71: ...ZERO TURN MOWER 70 ...

Страница 94: ...95 CHAPTER 7 TROUBLESHOOTING ...

Страница 95: ...96 ZERO TURN MOWER ...