42

2

INSTALLATION PROCEDURE

302.061

ERROR

CAUSE

SOLUTION

During feed, the bar is at a position

past that given by

parameter 5 plus parameter 6

.

The value of

parameter 5

is too

high.

Check the value of

parameter 5

based on the length of the piece to

be machined.

The lathe bar stop is not in the cor-

rect position.

Check the correct position of the bar

stop on the lathe.

Encoder fault.

Check that the encoder is driven

correctly in the rotation .

Check on the display the position of

the bar pusher carriage, and verify

that the position change indicated

corresponds to the actual move-

ment.

ERROR

CAUSE

SOLUTION

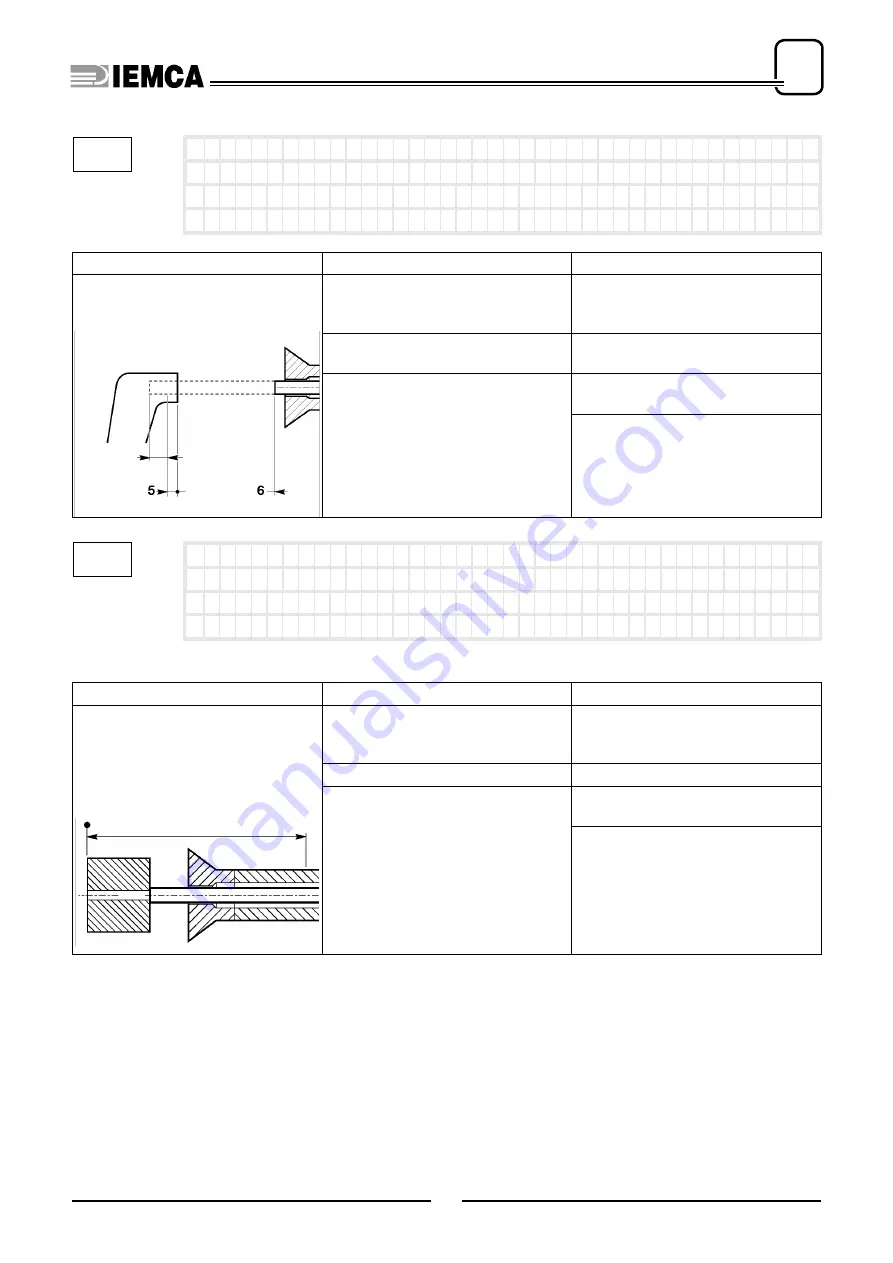

The bar moves along the section

defined at

parameter 11

, clears the

first obstacle (the collet), but stops

when it meets a second obstacle

(bushing or other).

The bar has met with an obstacle

past the impulse window (10 mm)..

Check the play of the bushing and

the presence of foreign bodies (bar

scraps or tool chips).

The push on the bar is not sufficient. Check the value of

parameter 13

.

Encoder fault.

Check that the encoder is driven

correctly in the rotation .

Check on the display the position of

the bar pusher carriage, and verify

that the position change indicated

corresponds to the actual move-

ment.

11

E r r o r : l o n g

f e e d

IDM - 61.023 Ec.0

parameter

parameter

error 11

12

E r r o r : s t a t i o n a r y

p o s i t i o n

a f t e r

i m p u l s e s

C

parameter 11

IDM - 61.020 Ec.0

Содержание VIP 80

Страница 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

Страница 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

Страница 52: ...MACHINE MAINTENANCE 7 302 028 49 7 2 3 Lubricating points fig 4 Lubricate Lubricate 4 28_063_3 bmp ...

Страница 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Страница 64: ...2 302 061 ...

Страница 74: ...12 1 GENERAL INFORMATION 302 061 ...

Страница 136: ......

Страница 138: ......

Страница 142: ...302 061 B ...

Страница 144: ......

Страница 148: ......

Страница 150: ......

Страница 152: ......