MACHINE MAINTENANCE

7

30

2.

0

2

8

- 47 -

7.2.

PERIODIC MAINTENANCE - TABLE

7.2.1

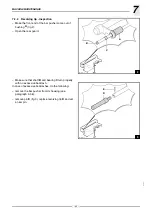

Air filter unit - Check

❑

Filter (A)

– Check if cup

B

is not full of condensate. If need be,

drain through valve

C

.

❑

Lubricator (D)

– Make sure that the oil level is not under the height of

suction.

To top up, do the following:

– disconnect the compressed air supply;

– unscrew plug

E

or cup

F

to fill the tank; the oil level

shall reach the

MAX

. reference.

Oil properties: 9 to 11 cSt at 40°C ISO VG 10.

– Reset the compressed air supply.

– Check the air lubrication (1-12 drops per 1000 l air);

adjust through screw

G

.

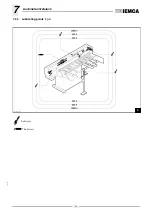

FEEDER

SECTION

OPERATIONS

FREQUENCY

HOURS

Periodically

200 1250 2000

Feed chain

Tension check

and adjust-

ment

•

Air filter

Check

•

Revolving tip

Check

•

AIR LUBE OIL COMPARATIVE TABLE

BP ENER-

GOL HP10

SHELL

TELLUS C10

MOBIL

DTE 21

ESSO

SPINESSO 10

28.081 Ec.0

MAX

•

A

G

E

•

F

•

B

C

D

Содержание VIP 80

Страница 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

Страница 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

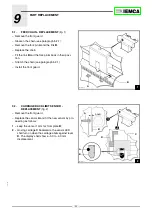

Страница 52: ...MACHINE MAINTENANCE 7 302 028 49 7 2 3 Lubricating points fig 4 Lubricate Lubricate 4 28_063_3 bmp ...

Страница 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Страница 64: ...2 302 061 ...

Страница 74: ...12 1 GENERAL INFORMATION 302 061 ...

Страница 136: ......

Страница 138: ......

Страница 142: ...302 061 B ...

Страница 144: ......

Страница 148: ......

Страница 150: ......

Страница 152: ......