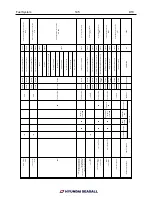

Fuel System

134 Fuel Delivery System

Common Rail Fuel Injection System (CRDI)

Fuel

temperature

sensor

Rail pressure

sensor

Water in fuel

sensor

Feed

pump

Injector

Common rail

High

pressure

pump

Main

fuel

filter

Pump

pressure

regulator

valve

Rail

pressure

regulator

valve

Fuel tank

Fuel feed (low)

Fuel feed (high)

Fuel return

return

return

return

return

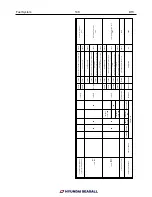

Fuel

temperature

sensor

Rail pressure

sensor

Water in fuel

sensor

Feed

pump

Injector

Common rail

High

pressure

pump

Main

fuel

filter

Pump

pressure

regulator

valve

Rail

pressure

regulator

valve

Fuel tank

Fuel feed (low)

Fuel feed (high)

Fuel return

return

return

return

return

Low Pressure Fuel Circuit

Low Pressure Fuel Pump

The low pressure fuel pump is either an electric fuel

pump with pre-filter, or a gear-type fuel pump. The

pump draws the fuel from the fuel tank and continually

delivers the required quantity of fuel in the direction of

the high pressure fuel pump (via fuel filter).

Fuel Filter

The fuel filter is located in between the low pressure

fuel pump and the high pressure fuel pump and filters

the fuel delivered from the fuel tank.

High Pressure Fuel Circuit

High Pressure Fuel Pump

The high pressure fuel pump compresses fuel up to

1,600 bar and delivers the compressed fuel to the

common rail

Common Rail

The two common rails are installed on bank 1 and 2

and are connected with the high pressure fuel pump

and the injectors by the high pressure fuel pipes. This

rail stores the fuel compressed in the high pressure fuel

pump. So that the two rails have same fuel pressure,

the high pressure fuel pipe connects the two rails. The

ECM controls the fuel pressure of the common rail by

using the rail pressure sensor and the rail pressure

regulator valve installed on the common rail (Bank 1)

and (Bank 2) respectively.

Injector

The injector injects the high pressure fuel stored in the

common rail into the cylinder by the ECM control signal.

High Pressure Fuel Pump

The high pressure fuel pipe is a channel in high

pressure fuel circuit consisting of the high pressure fuel

pump, common rails, and injectors. It is a steel tube

which can withstand high frequency generated when

the fuel pressure reaches the maximum pressure or

fuel injection stops.

The differences in length between the common rail and

the individual injectors are compensated for by using

slight or pronounced bends in the individual lengths of

tubing. Nevertheless, the injection lines should be kept

as short as possible.

Содержание S220P

Страница 3: ...Engine Mechanical System 2 General Information General Information Specifications ...

Страница 4: ...Engine Mechanical System 3 General Information Specifications ...

Страница 5: ...Engine Mechanical System 4 General Information Specifications ...

Страница 10: ...Engine Mechanical System 9 Cooling System Special Service Tools ...

Страница 11: ...Engine Mechanical System 10 Cooling System Special Service Tools ...

Страница 18: ...Engine Mechanical System 17 Cooling System ...

Страница 19: ...Engine Mechanical System 18 Cooling System Thermostat ...

Страница 55: ...Engine Mechanical System 54 Lubrication System ...

Страница 73: ...Engine Electrical System 72 General Information Troubleshooting Charging system ...

Страница 74: ...Engine Electrical System 73 General Information Starting system Special service tools ...

Страница 75: ...Engine Electrical System 74 Charging System Charging system Alternator ...

Страница 80: ...Engine Electrical System 79 Starting System Components ...

Страница 91: ...Fuel System 90 General Information Special Service Tools ...

Страница 112: ...Fuel System 111 Diesel Control System EOI Engine Operating Indicator System Circuit Diagram 1 ...

Страница 117: ...Fuel System 116 Diesel Control System Specification Circuit Diagram ...