13

CLEANING, SANITIZING, AND CARTRIDGE REPLACEMENT

NO WATER FLOW MONITOR:

Complete Steps 26 - 29

OPTIONAL SMARTAP

®

WATER FLOW MONITOR:

Complete Steps 18 – 29

NOTE:

The water flow monitor and battery are mounted

inside the manifold cover.

Monitor must be reset to zero each time system is

serviced and cartridges replaced.

If monitor is not reset, there is no way to determine

when filters were changed or if the system is still

operating within specifications.

Monitor is reset when the battery is disconnected

from the clip.

Installing a new battery when filter cartridges are

replaced ensures an accurate indication of system

performance and a continuing supply of high

quality drinking water.

Failure to replace battery may result in yellow light

when system is reconnected.

Use caution when working with module. The

wiring therein connects the control board to the

sending unit. If these wires are damaged, the

monitor will not function.

Do not get the monitor components wet (includes

circuit board, phone jack, and battery connections).

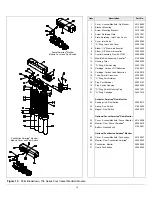

18. Loosen three mounting bracket screws. Gently pull

module cover up and away from module body.

19. Disconnect the battery. The connection to the battery

is a snap type connector (See Figure 11).

20. Remove the battery by sliding it out of its holder.

21. Replace the battery with a new alkaline 9-volt transistor

battery (P/N 31300001).

22. Carefully slide the battery into its holder.

NOTE:

Use caution when reconnecting the battery (See

Figure 11).

23. Reconnect the battery by pressing the clip onto the

battery terminals.

24. Replace the module cover and tighten bracket screws.

25. Turn feed water valve slowly to the open position.

26. To test the connections, activate the Smartap

®

monitor

by pressing the test button or opening the product

water faucet. If an indicator light illuminates,

connections are good.

27. Open product water (and extra point-of-use) faucet.

Let water flow until all air has been expelled from

system.

28. Close product water (and extra point-of-use) faucet. In

5 minutes, check the connections for leaks and correct

if necessary.

Icemaker: Let the tray/bin fill with ice cubes. Discard

all ice cubes to the drain. This flushes sanitizing

solution from the lines to the icemaker.

29. Open product water (and extra point-of-use) faucet.

Let the water flow for 10 minutes. This will expel any

remaining air from the system.

NOTE:

The system is ready to use. Should there be any

aftertaste or odor to the water or ice cubes, repeat

Step 29.

Figure 11

Smartap

®

Battery Connection