INSTALLATION REQUIREMENTS

READ THIS ENTIRE INSTALLATION AND SERVICE GUIDE BEFORE BEGINNING INSTALLATION

This Aquafier

®

Drinking Water Treatment System is designed for ease of installation and serviceability.

It is constructed with the finest materials available.

Using these instructions and paying close attention to parameters outlined within "CONDITIONS FOR USE" detailed

on Page ii will ensure a successful installation.

This system must be installed in accordance with applicable city, state, and local plumbing codes.

To insure the system continues to operate at its optimum level,

it is necessary to have a routine maintenance and replacement schedule (Page 11).

The frequency at which filters need changing will depend on quality of feed water supply and level of system usage.

PREPARATION

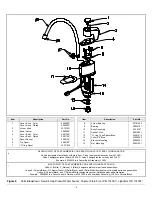

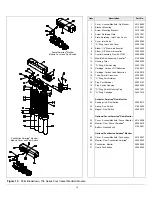

1. Check that all appropriate components are packed

with your system (Page II, Figure 1). Refer to

applicable Component Parts Breakdown (Figure 7, 9,

or 10) for a complete list of its constituent parts.

2. Determine locations for component installation. Two

requirements for consideration are: access to cold

water supply line and to household sink. Specific

requirements are detailed in Table 1.

PRODUCT WATER FAUCET

FILTRATION MODULE

Faucet may be installed in any convenient location.

Make sure underside of location is free of obstructions.

Module may be installed under a sink or in any convenient

location. within 15 feet of source water supply and faucet

* DO NOT PLACE MODULE WHERE IT WILL BE EXPOSED TO FREEZING AND/OR DIRECT SUNLIGHT.

Mount Module on side of cabinet using bracket (attached to Module) and two screws provided in the Installation Kit.

HOLD THE MODULE BY THE FILTER HOUSINGS WHEN PICKING UP OR CARRYING THE UNIT

Table 1

Component Location Requirements

NOTE

THIS DRINKING WATER SYSTEM IS FOR USE ON POTABLE WATER SUPPLIES ONLY.

COMMONWEALTH OF MASSACHUSETTS PLUMBING CODES 248 CMR SHALL BE ADHERED TO.

CONSULT WITH YOUR LICENSED PLUMBER FOR INSTALLATION OF THIS SYSTEM.

CAUTION

DO NOT USE WITH WATER THAT IS MICROBIOLOGICALLY UNSAFE OR OF UNKNOWN

QUALITY WITHOUT ADEQUATE DISINFECTION BEFORE OR AFTER THE SYSTEM.

SYSTEMS CLAIMING CYST REDUCTION

SYSTEMS CERTIFIED FOR CYST REDUCTION

MAY BE USED ON DISINFECTED WATERS THATMAY CONTAIN FILTERABLE CYSTS.

IF SIGNIFICANT INLET WATER PRESSURE DIFFERENTIALS OCCUR, PRESSURE REGULATOR MUST BE USED.

III