- 5 -

PRODUCT WATER FAUCET SITE PREPARATION

Refer to Faucet Installation Instructions (Pages 6 and 8) for site location and mounting hole

specifications.

Primary considerations for site selection are convenience of use and an open area under sink.

Always check underside of selected location for obstructions.

PORCELAIN/ENAMEL OVER STEEL

OR CAST IRON SINKS

NOTE:

A heavy duty, variable speed drill motor is

recommended for this procedure.

Use of a spring-loaded porcelain drill set is

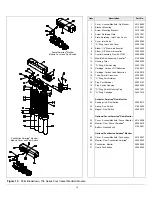

strongly recommended (Figure 5).

Plastic sleeve supplied on pilot drill (Figure 5.A.)

is to be positioned on drill bit against drill chuck.

This prevents chuck from contacting porcelain

after pilot hole has been completed.

Suggestion: Practice on discarded sinks to familiarize

yourself with operation of porcelain cutter kit.

CAUTION:

Avoid high motor R.P.M. during initial

penetration of porcelain, as high drill speed

will cause excessive chipping.

1. Using carbide tipped bit with plastic sleeve (Figure

5.A.), drill pilot hole completely through porcelain and

metal underneath.

2. Place spring-loaded porcelain saw (Figure 5.B.) into

drill chuck. Make sure pilot guide is inserted tightly.

Insert pilot guide into pilot hole. Push down gently on

drill motor to apply light pressure to porcelain surface.

Start drill motor turning as slowly as possible.

After initial cut has started, motor speed may be

gradually increased. The cut may require three to

four minutes to complete. Going faster could result in

excessive chipping. Be sure a complete ring has

been cut through porcelain to material underneath.

3. Place finish hole saw (Figure 5.C.) into drill chuck.

Make sure pilot guide is inserted tightly. Insert pilot

guide into pilot hole. Begin cut using a slow speed

and light pressure until porcelain (inside ring cut in

Step 2) has been penetrated to material underneath.

4. Remove saw from hole and clean all debris from

porcelain surface. Reinsert saw into hole and cut

through remaining material.

TILE COUNTER TOP

1. Follow procedures detailed in section labeled

"Porcelain/Enamel Over Steel" (substitute "tile" for

"Porcelain" in instructions).

STAINLESS STEEL SINK

1. Use a center punch to make a small indentation to

mark center of desired location.

2. Drill a pilot hole with a 1/8" metal drill bit, then enlarge

hole with a 3/8" metal drill bit.

3. Complete hole size by using a 1 1/4" chassis punch

available from your dealer (P/N 36201006).

NOTE:

Installation hole is ready, install faucet.

A. PILOT

DRILL

B. SPRING LOADED PORCELAIN SAW

C. FINISH HOLE SAW