●

Usage Precautions 1-7

i. JP-T71 and JP-T75 will change color if retorting processing (heating with hot

water or steam) is done after printing. Since water is necessary for change of

color, the change will not occur if heating is done with hot air. Be sure to perform

ex ante evaluation for color changeability. Degree of change will vary depending

on the conditions of printing matter, retorting device or retort processing. Confirm

the change in the condition being used.

(1) Items to be checked befor using:

Change of color

CAUTION

(1)Change of color is caused by element seeping as a result of boiling or

use of condensed steam.

(2)Water is necessary for change of color. No change of color will occur if

heating is done with hot air.

(3)Reference condition for change of color by heating with steam is 120

℃

for 20 minutes. However, if stream of steam in retorting device is not

sufficient, change of color may not occur, or color may change

unevenly. And the degree of change may vary depending on the

position inside the device, retort food, canned content or contents of

printed matter.

(4)Reference condition for change of color by heating with boiled water is

100

℃

for 20 minutes. However, seeped dye may stain, color blur may

occur or poor change of color may occur, due to uneven temperature

inside retorting device, flow or retention of hot water on printed surface.

And the degree of change may vary depending on the position inside

the device, retort food, canned content, surface tempurature of can or

contents of printed matter.

(5)Change of color does not guarantee that sterilization has been perfectly

performed, nor does the case when color does not change always

indicate that heating has not been performed.

(6)Change of color tone will vary depending on material of printed matter,

shape, surface condition and hue. Especially, when printing is done

with dark color, change may not be clearly indicated.

(1)Change of color is caused by seeping of dye. So, in cause before

change of color, the elution test standard for appliance and container

specified by food hygiene law will not be satisfied. However, the

standard will be satisfied after change of color: If used for food

container, be sure to confirm change of color. (JP-T71)

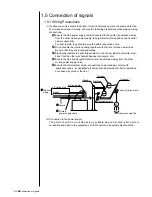

Boiling,

condensed water

j. Caution of JP-K77, JP-K81 and JP-K86

(1) When handling ink or makeup, take enough care not to spill ink or makeup.

If you spill any ink or makeup by accident, wipe it off completely and promptly

with wiping paper or something similar.

Be sure to close the maintenance cover after the portion where you wiped is

completely dry, because vapors of ink or makeup staying inside the printer

may catch on or cause a fire.

(2) Never remodel the printer.

(3) Never let the printer run is case the cooling fan is not working.

(4) Acetone is used as solvent for JP-K77, JP-K81 and JP-K86. Acetone has

characteristics of high vapor pressure (evaporable) compared with MEK, so

take care to with the following:

・

Reference period for long-term shutdown will be shorter. Operate printer

within the reference period periodically, or perform maintenance work for

long-term shutdown if shut-down time exceeds reference period.

If the printer is shut down longer than reference time, re-start may not be

possible due to settling of remaining ink component.

K. Caution of JP-E78

(1) If printed mark is boiled or soaked in water, printed characters may fade.

(2) Do not charge JP-E78 to a printer in which any other type of ink has been

used: Ink components may mix before printing.

Содержание PXR-D

Страница 302: ... Outside Dimensions 13 1 13 Schematic Diagrams 13 1 Outside Dimensions Fig 13 1 Model PXR IJ printer outside dimensions ...

Страница 306: ... Electrical Connection Diagram 13 5 13 2 Electrical Connection Diagram Fig 13 5 Electrical connection diagram ...

Страница 307: ...13 6 Circulation System Diagram 13 3 Circulation System Diagram Fig 13 6 Circulation system diagram ...

Страница 319: ...3S23L1307 3B PXR D E7 HEC ...