www.hi-velocity.com

© 1995-2017 Energy Saving Products Ltd.

Start

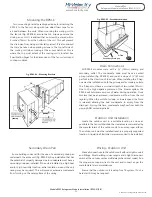

Fig. 008

Fig. 003

Fig. 006

Fig. 005

Use

Clamp

on Amp Meter to

test

Amperage

of input power

supply to the fan coil.

(Fig. 008)

PSB Circuit Board

&

WEG

Drive

functioning correctly

Motor

running?

Motor

working correctly

Call Technical Support @

1-888-652-2219.

PSB circuit board is

working correctly -

Replace

WEG controller

17

16

15

14

18

Y

N

Y

N

Call Technical Support Toll

Free 1-888-652-2219

Amperage

> 2A

(1 amp @ 220-240 volt AC)

Voltage Present

? (0-10VDC)

VDC > 9VDC

PSB Circuit Board

is

Functioning Correctly

Increase

appropriate PSB

trimpot

1/2 turn Clockwise

-

Wait

30 seconds

for

motor to adjust

Voltage

present?

Continue to

Step 11

1

10

12

Y

Y

N

N

11

Ensure

Transformer

is

connected properly

Inspect

Supply Voltage

-

Return to

Step 5

Supply Power

Present?

Verify that

24VAC

is

present between

R & C

on

the PSB circuit board

(Fig. 005)

Verify that

24VAC

is

present between

C &

desired T-Stat

setting

Ensure that

Jumper

is installed correctly

(Fig. 001)

Replace

Transformer

Turn off

Supply Power

, connect

transformer, turn on power -

Return to

Step 6

Call Technical Support

Toll Free 1-888-652-2219

Install

Jumper

and

return to

Step 7

9

8

7

6

5

Verify that

Main Supply Voltage

is

present on the PSB circuit board

between the

L and N terminals

(Fig. 004)

4

Power

Fan Coil

3

N

N

N

Y

Y

Y

N

Y

N

N

Y

Unplug Motor Leads

and

test resistance (ohms)

between Windings

(Figs. 002 & 003)

Jumper desired Tstat setting

with

R

on the PSB Circuit Board

(Fig. 001)

Verify that

Pressure Sensing

section

of PSB is functioning properly

by measuring

Voltage Output

(Volts DC) @ the WEG controller,

terminals

7 & 8

(Fig. 006)

2

Y

Call Technical Support

Toll Free 1-888-652-2219

X

If R

esistance

is outside of the

acceptable range

(6.5 - 10.5 ohms) or uneven

across any winding legs,

call Technical Support

Toll Free @ 1-888-652-2219

-

If

Resistance

is acceptable,

re-connect

Motor Leads

and

continue to

Step 3

Adjust Trimpots

on PSB

Circuit Board until airflow is

running at desired speed

*See

System Commissioning

and Set-Up.

Continue adjustments

until

VDC > 9VDC

-

Return to

Step 12

Resistance

should be

equal

between all

Windings

. Black to

Red, Black to White and Red to

White.

Resistance

should be:

6.5 - 10.5 ohms

Troubleshooting - Motor Running Too Slow

-44-

Module HE-Z DIA Diagnostics &

Trouble Shooting (3/8)

Module DIA Diagnostics & Trouble Shooting (3/8)

Fig. 002

Fig. 001

Input Voltage

and

T’Stat section

on PSB is functioning correctly

Ensure that

Volt Meter

is set

to read

Volts DC

- Test

Voltage on opposite end of

Cable

(Fig. 007)

Fig. 007

Fig. 004